- Joined

- Jul 29, 2014

- Messages

- 2,725

I can’t see that a 200 pound lathe needs anything very unique. A card table might be a bad idea, but about anything else should work.

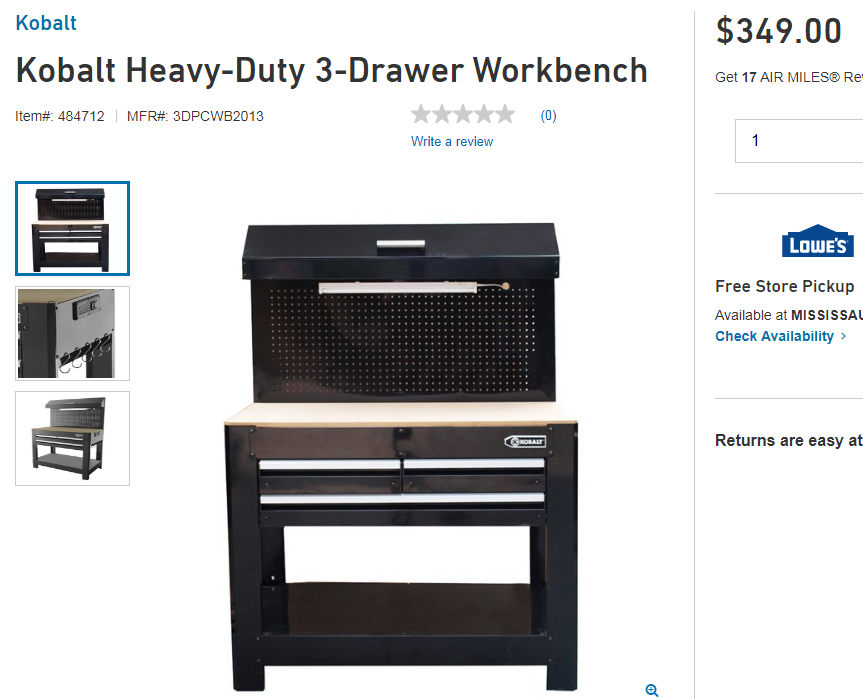

Maybe this, but seems a bit lightweight

Those are canadian dollars, equivalent to about 269 USD

Which leveling casters did you use for the U.S. General cabinet? The caster mounting plates on this toolchest are larger than standard, and I haven't found a leveling caster that would mount directly on it. Did you have to fashion an adapter plate?

@twowhites I made custom mount plates from a 4" wide chunk of 1/4" steel. It's a little tricky as you need holes for the tool box and tapped holes for the casters. I'll see if I can get my phone down there and get a decent pic, but it's just takes some planning.Which leveling casters did you use for the U.S. General cabinet? The caster mounting plates on this toolchest are larger than standard, and I haven't found a leveling caster that would mount directly on it. Did you have to fashion an adapter plate?

The photo would be greatly appreciated. Are you happy with the brand of leveling casters you used? There are a whole lot of choices out there and some of them get really pricey.@twowhites I made custom mount plates from a 4" wide chunk of 1/4" steel. It's a little tricky as you need holes for the tool box and tapped holes for the casters. I'll see if I can get my phone down there and get a decent pic, but it's just takes some planning.

Here you go... not easy to get pix of them...The photo would be greatly appreciated. Are you happy with the brand of leveling casters you used? There are a whole lot of choices out there and some of them get really pricey.