- Joined

- Jan 31, 2016

- Messages

- 11,423

Sometimes I think this was the only tool in some of my co-workers' toolboxes .

$40 well spent. Half was on the Foster bros cleaver.

Sometimes I think this was the only tool in some of my co-workers' toolboxes .

$40 well spent. Half was on the Foster bros cleaver.

And if you were lucky they hadn't stolen yours!Sometimes I think this was the only tool in some of my co-workers' toolboxes .

They got quite a lot from me when being off for 10 months , but not my clever !And if you were lucky they hadn't stolen yours!

Very cool, I have a feeling this one will take quite a while to spin down aswell, but i've yet to power her up.I have one that is very similar. Runs very smooth, and takes about 10 min for it to coast down when you shut it off. Mike

Very pretty old girl!Awesome grinder.

A truely beautiful piece of machinery.

I have a bit of a jones for big Old grinders and would love to have a 2x12.

Have some grinding to do on a battleship

I missed out on two of them of late.

One at an auction and one at a guys place where I bought another piece of machinery. He wouldn't sell it.

I have your grinder's little sister here.

Same manufacturer.

I did a rehab on it a couple of years ago.

It was on a crude stand. I mounted it on an axle housing from a Ford tractor.

You will cry if you ever have to buy new stones for yours.

I did when I bought these little 1 1/2 X 10

Cost nearly four times as much as I paid for the grinder.

Just curious. In all the time on this planet, did anyone ever explain what TMI means?Getting old sux! This is my 5th time.

View attachment 451757

Now that is just plain sexy...great score.Some might enjoy this, after years of looking, I finally found a nice USA made pedestal grinder that is in good shape, it was wayyyy in Rockford Illinois!

But I couldn't resist, so I purchased her, lined up a truck and the paperwork to ship her to Canada Bc.

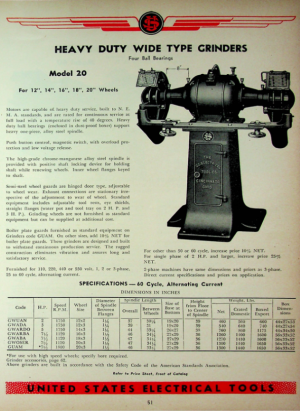

It arrived last week, was installed into the original location in 1928, it's a us electrical tool company with all the bells and whistles, model 20, 12x2" stones 3hp

View attachment 451590View attachment 451591View attachment 451593