- Joined

- Nov 14, 2016

- Messages

- 2,997

So this metric threading device followed me home...

I've always been curious about these 9x20 lathes and one was available about 30 miles away at an extremely reasonable price. Damn that Craigslist!

Seriously though it was cheaper than buying a set of metric thread cutting gears for my Powermatic lathe, so that was my justification. I'll leave this one set up for metric threading. That is my story anyway, and so what if I never work in metric.

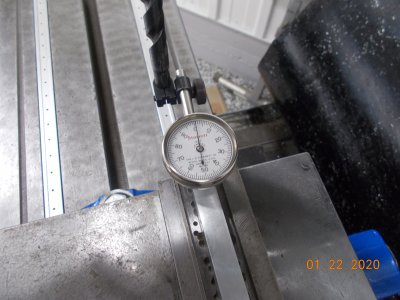

Very little tooling with it, just the 4" chuck and a drill chuck in the tail stock. It has the same spindle thread and tail stock taper as my 10x24 so a lot of my existing tooling will cross pollinate. It looks practically new despite being almost 26 years old, very clean, no rust or signs wear, everything is tight, just a few minor cosmetic blemishes. I've literally bought new stuff at Harbor Freight that was in worse condition. It is an older model so almost no plastic in it.

Ignore the dinged up handles, my clumsy ass caught the door frame bringing it in and boogered up the handles on the cross slide and compound. Already checked Grizzly and $20 should take care of that.

I've always been curious about these 9x20 lathes and one was available about 30 miles away at an extremely reasonable price. Damn that Craigslist!

Seriously though it was cheaper than buying a set of metric thread cutting gears for my Powermatic lathe, so that was my justification. I'll leave this one set up for metric threading. That is my story anyway, and so what if I never work in metric.

Very little tooling with it, just the 4" chuck and a drill chuck in the tail stock. It has the same spindle thread and tail stock taper as my 10x24 so a lot of my existing tooling will cross pollinate. It looks practically new despite being almost 26 years old, very clean, no rust or signs wear, everything is tight, just a few minor cosmetic blemishes. I've literally bought new stuff at Harbor Freight that was in worse condition. It is an older model so almost no plastic in it.

Ignore the dinged up handles, my clumsy ass caught the door frame bringing it in and boogered up the handles on the cross slide and compound. Already checked Grizzly and $20 should take care of that.