- Joined

- Jun 11, 2019

- Messages

- 84

Bison makes good chucks! Expensive, but good.

Old beat up 12" I've got still hold .001" after 15 years of hard use.

Bison makes good chucks! Expensive, but good.

I reckon you'll be making some mini lathes now for the H-M community?????Haha I guess I should share the rest, I don't really have a picture of it all together with the enclosure and electrical cabinet, but here it is

View attachment 427700

Hahaha that would sure be lots of workI reckon you'll be making some mini lathes now for the H-M community?????

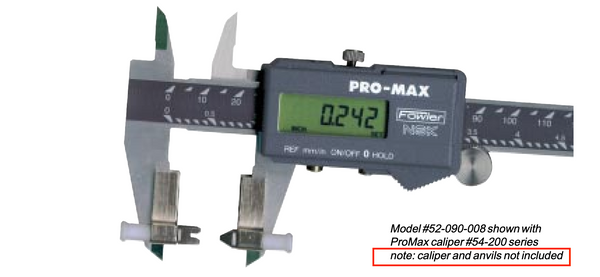

This is a blade mike, handy for measuring the diameter of grooves and other hard to reach features. Screw thread micrometers either have a set of interchangeable anvils to handle a range of pitches, or handle only a narrow range. A pair of anvils consists of a vee-point and matching notch. Around $60 new on eBay:Just another write-off, the reason I won't pay much up front. If it works out, I will buy another one new. Although I did beat out a couple of other bidders. What I wanted to do is measure the "root?" diameter of a screw. But the anvils are too thick (~0.020") to measure the small (<1/4-20) threads I deal with. They will do fine, I guess, for a 5/8' bolt and things of that size. But even with the slight angular meeting of the anvils, they are thicker than the pitch of most of my work. Ces la Vie', $h!t happens. . . I'll just stick to a good caliper with sharp edges, and my understanding of screw threads to determine drill sizes.

View attachment 428091