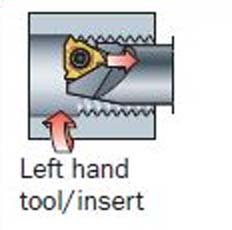

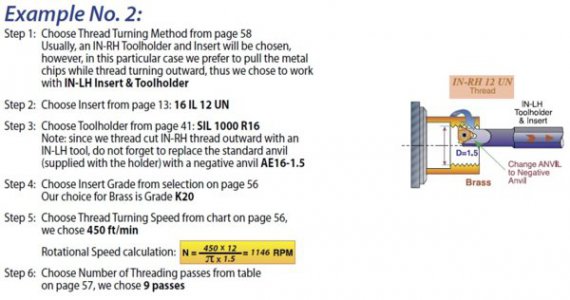

I Am about to purchase a left hand threading boring bar and inserts to do right hand internal threading using the reverse helix method. I need to purchase a boring bar and the inserts but I have some questions.

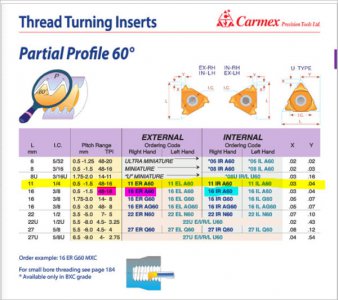

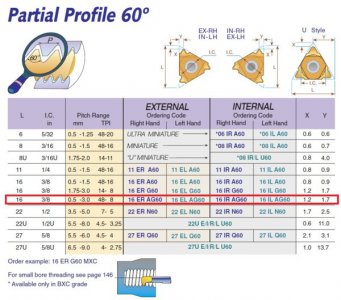

The thread boring bar I am looking at is a left hand bar that says it accepts ER11 inserts. I know that ER stands for external thread and IR stands for internal thread but when using the reverse helix right hand internal threading method do you use ER inserts or IR inserts? The bar I am looking at is in the link below:

https://www.ebay.com/itm/SNL0012K11...e=STRK:MEBIDX:IT&_trksid=p2055119.m1438.l2649

The thread boring bar I am looking at is a left hand bar that says it accepts ER11 inserts. I know that ER stands for external thread and IR stands for internal thread but when using the reverse helix right hand internal threading method do you use ER inserts or IR inserts? The bar I am looking at is in the link below:

https://www.ebay.com/itm/SNL0012K11...e=STRK:MEBIDX:IT&_trksid=p2055119.m1438.l2649