- Joined

- Jul 9, 2018

- Messages

- 314

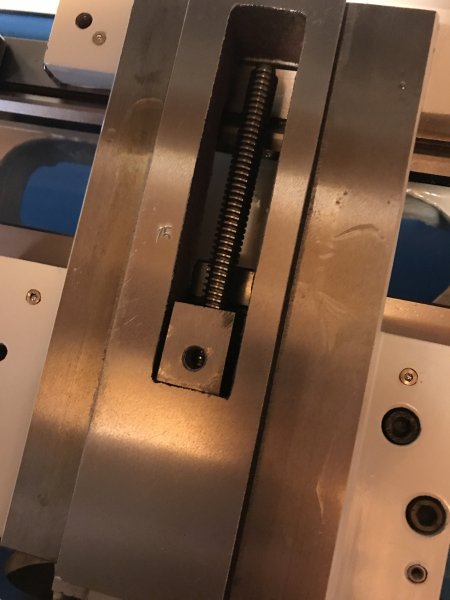

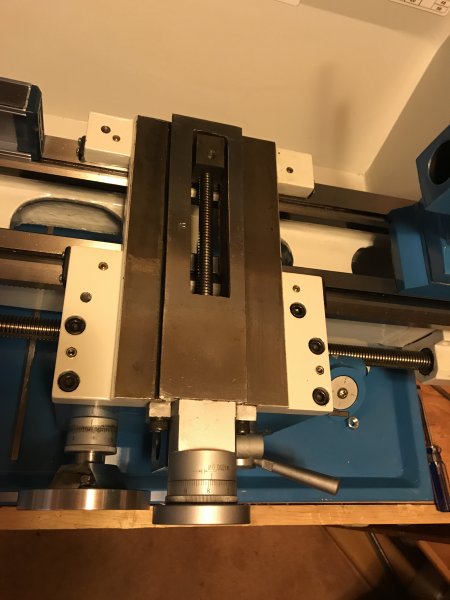

Oh no what have I done, its in the house now...

I will think about putting some plywood down over my old carpet.

I have a downstairs storage but its not sealed, it floods in the winter and only 3 walls are sealed, one is a vented lattice type.

I am amazed with all the knowledge on this forum. So much to learn about and do before making my 1st chips.

Hope you all get a good laugh about this being my second lathe, tons of experience on it...HAHA

I will think about putting some plywood down over my old carpet.

I have a downstairs storage but its not sealed, it floods in the winter and only 3 walls are sealed, one is a vented lattice type.

I am amazed with all the knowledge on this forum. So much to learn about and do before making my 1st chips.

Hope you all get a good laugh about this being my second lathe, tons of experience on it...HAHA

Last edited: