- Joined

- Jun 27, 2016

- Messages

- 378

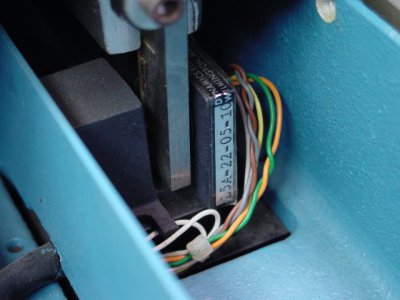

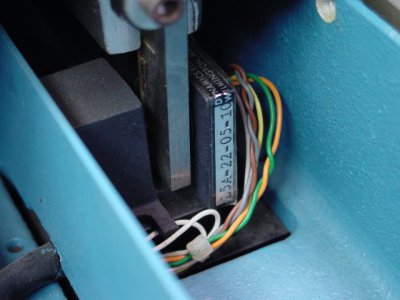

While cleaning up the man cave, I found these which I got in 2005. Really high end linear stages that came out of Silicon Valley. They have glass scales, DC servo motors and they are a matched set in the XY direction. Back when I received them I called the manufacture to get more info, the rep said they cost over $10k at the time. Got any ideas what to do with them, a mill, 3d printer, router?