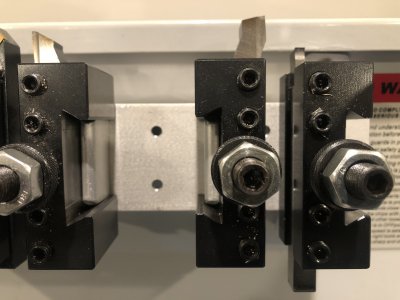

In the picture below, from L to R:

(1) RH turning tool: use for turning toward the headstock (medium size)

(2) Internal threading (medium size)

(3) Internal threading (small size)

(4) Chamfer tool

(5) Part/Groove

(6) Unknown to me (?). I have used it to chamfer, but I don’t know what they mean this to be used for (small size)

(7) Same answer as (6) above (medium size)

(8) RH turning tool. Use for turning toward the headstock (small size)

(9) Internal threading (small size)

(10) LH facing tool. Use for facing.

Note that sometimes people use the above tools outside of the above designations. I’m sure I’m not the only person who uses their threading tool to put on a chamfer now and then.

Another example of this would be that if you were turning away from the headstock, you would use tool (10) above.