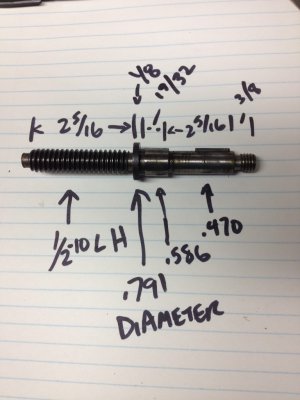

I broke the tail stock lead screw on my AT300 (no-name manufacturer). It would be a quite easy one to fabricate, but someone threw the broken screw away, so I don't have amything to measure or look at to get the dimensions

does anyone know of a place where they sell replacement parts like this? Or maybe someone would be so kind to me and measure your own and make me a drawing? I would greet the favour by making two screws and send one to whoever provided me a drawng

thanks for any info!

Edward

does anyone know of a place where they sell replacement parts like this? Or maybe someone would be so kind to me and measure your own and make me a drawing? I would greet the favour by making two screws and send one to whoever provided me a drawng

thanks for any info!

Edward