I'm not sure how you guys measure by Bits. Is a bit = to a mile?Yeah, just a bit north ...

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which mill on 2k budget

- Thread starter Abody711

- Start date

- Joined

- Nov 14, 2016

- Messages

- 2,996

As others have mentioned the price of the mill is just the start. You need to figure a minimum of $500-1000 just for the basics, vise, parallel set, collet set, end mills etc needed to start using the machine. $2500 would be a decent budget to get you started with a PM-25 but that is a smaller mill.

Personally at the price I wouldn't even consider the Jet. RF-31 type mills like that Jet are common used at half that price or less, often with a vise and tooling included. Lots of members here have round column mills, so they aren't bad, just that at $2500 I think there are better options.

A smaller mill is an option if your work will fit, but don't go that way just to fit your budget. You can always add tooling later, but if you buy a machine that is inadequate to your needs there is no easy way to make it bigger other than buying a bigger mill. 7x27 vs 8x33 doesn't seem like much, but the PM30 is a more capable machine than the PM25.

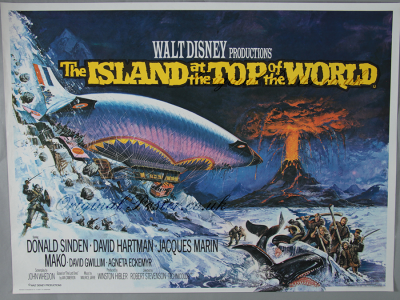

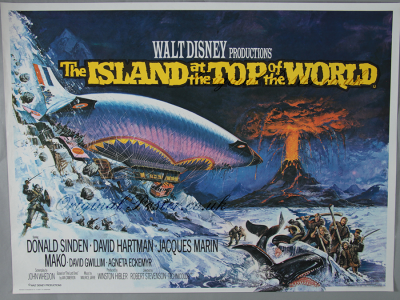

When it comes to the budget I feel like I started off just building a snowman and then I ended up in this poster.

Personally at the price I wouldn't even consider the Jet. RF-31 type mills like that Jet are common used at half that price or less, often with a vise and tooling included. Lots of members here have round column mills, so they aren't bad, just that at $2500 I think there are better options.

A smaller mill is an option if your work will fit, but don't go that way just to fit your budget. You can always add tooling later, but if you buy a machine that is inadequate to your needs there is no easy way to make it bigger other than buying a bigger mill. 7x27 vs 8x33 doesn't seem like much, but the PM30 is a more capable machine than the PM25.

Yeah, just a bit north ...

When it comes to the budget I feel like I started off just building a snowman and then I ended up in this poster.

- Joined

- Nov 28, 2016

- Messages

- 2,344

I'm not sure how you guys measure by Bits. Is a bit = to a mile?

Just judging by the context, I would say a bit would be equal to several miles, at least...

-Bear

- Joined

- Jan 10, 2019

- Messages

- 1,042

I'd first ask the OP, "must it be new?" That compartmentalizes the answer.

I wish that people who start threads like this would more actively participate. Otherwise, it comes across a bit like "My time is valuable, so you guys do all the work to provide me answers until I can stop back in at my leisure." Or not.

I wish that people who start threads like this would more actively participate. Otherwise, it comes across a bit like "My time is valuable, so you guys do all the work to provide me answers until I can stop back in at my leisure." Or not.

Last edited:

- Joined

- Mar 3, 2020

- Messages

- 506

In this instance a bit sounds like a boat buck.

A boat buck is a $100. bill.

A boat buck is a $100. bill.

I am glad to participate in the thread but being a novice I have little to add. Used machines in my area come under slop acceptable for its age. I do not want something to work on but rather have something to work with. That is the reason I am looking at new.

- Joined

- Sep 8, 2019

- Messages

- 4,392

My two cents:

I have bought 3 new machines (2 lathes & a mill) in the last 12 months. In all 3 cases, I bought new Precision Matthews machines. So far, I have had zero problems. In fact, it has gone very smoothly, although I should mention that I ended up flattening the family finances.

I am sure that previously owned machines can deliver tremendous value, but the machine school that I go to uses (and sells) used machines, and I have seen a lot of slop (!) and issues that would not arise on a new machine. Working on these large but tired machines is usually great, but many are missing levers (and functions). Working on such worn machines may not provide as good of an operator experience as working on a machine that is new (even if that machine came from China or Taiwan).

I have bought 3 new machines (2 lathes & a mill) in the last 12 months. In all 3 cases, I bought new Precision Matthews machines. So far, I have had zero problems. In fact, it has gone very smoothly, although I should mention that I ended up flattening the family finances.

I am sure that previously owned machines can deliver tremendous value, but the machine school that I go to uses (and sells) used machines, and I have seen a lot of slop (!) and issues that would not arise on a new machine. Working on these large but tired machines is usually great, but many are missing levers (and functions). Working on such worn machines may not provide as good of an operator experience as working on a machine that is new (even if that machine came from China or Taiwan).

Last edited:

- Joined

- Jan 2, 2019

- Messages

- 6,509

So, what do you plan on working on? Do you have any other hobbies that might give us a clue as to what the smallest machine you can go with. Take the size comments seriously, it's better to stretch and get something that will work than go too small and have to upgrade before you even get much use out of it.

If you're just starting out and don't have any other machines or projects in mind could I suggest you look into getting a lathe first. There are things you will learn with a lathe that will help on any other machine you work with later. Mills are fun but lathes are more practical for a lot of home projects, there are also ways to use a lathe for the kinds of things normally done on a mill but not so much the other way around.

It doesn't matter if you don't know much now, we all started out that way and having a community like this can easily accelerate your learning curve.

John

If you're just starting out and don't have any other machines or projects in mind could I suggest you look into getting a lathe first. There are things you will learn with a lathe that will help on any other machine you work with later. Mills are fun but lathes are more practical for a lot of home projects, there are also ways to use a lathe for the kinds of things normally done on a mill but not so much the other way around.

It doesn't matter if you don't know much now, we all started out that way and having a community like this can easily accelerate your learning curve.

John

The only other hobby is firearms. I purchased am 8.7x27 lathe months ago. So I have the width to work on most barrels. The mill would be used to duplicate some hard to find parts for handguns that have been out of production for many years. Other than that, I have some possible projects for my Kubota tractor and grandkids go karts. Beyond that who knows

- Joined

- Jan 2, 2019

- Messages

- 6,509

Okay, good to hear you already have the lathe.

If you're working on anything to do with tractors you will want size and rigidity, It may not be easy to find but as others have pointed out reasonable used Bridgeport's or clones can be had in this price range. I tend to think if you take the time to learn how to evaluate older machines and be ready with cash you'll be able to get something good if you're patient. There are an awful lot of these machines sitting unused on farms and home shops, maybe even put out a wanted add on Craigslist or FB Marketplace.

If you want to buy new I'd up the budget by another $2k and get at least a 9x40 benchtop mill. Of course that's just my opinion and I don't own either but I am sure patience will be your friend here.

John

If you're working on anything to do with tractors you will want size and rigidity, It may not be easy to find but as others have pointed out reasonable used Bridgeport's or clones can be had in this price range. I tend to think if you take the time to learn how to evaluate older machines and be ready with cash you'll be able to get something good if you're patient. There are an awful lot of these machines sitting unused on farms and home shops, maybe even put out a wanted add on Craigslist or FB Marketplace.

If you want to buy new I'd up the budget by another $2k and get at least a 9x40 benchtop mill. Of course that's just my opinion and I don't own either but I am sure patience will be your friend here.

John