Alen,

Without knowing what your budgeting for your Tig purchase its hard to recommend one.

I will say to start with machine you won't out grow too soon. This one has a $700 rebate and can probably found a little better priced.

https://www.millerwelds.com/equipment/welders/tig-gtaw/diversion-180-tig-welder-m00337

If you plan on getting serious and require higher amperage than consider a water cooled set up but the cost goes way up.

I happen to be a fan of transformer machines but Tig units have come along way with inverter technology.

This is the setup I run with an upgraded torch.

https://www.millerwelds.com/equipme...30-460-v-foot-control-complete-package-951117

They are pricy, but transformer machine longevity has been proven to last. Not uncommon to find a 30+ year old Syncrowave for sale and in working order.

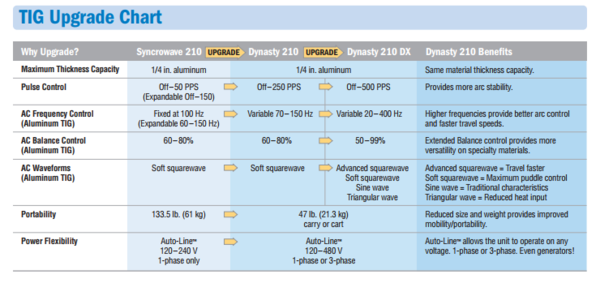

The latest and "greatest" TIG Miller offers are the Dynasty series. Very versatile with everything the Syncrowave has to offer and more. They have the ability chang the current frequency. This has made new users into pretty good TIG operators.

https://www.millerwelds.com/equipme...=dynasty-280-dx-208-575-v-tigrunner-907514001

Keep in mind, the Syncrowave and the Dynasty links are middle of the road miller offers. There is higher amperage machines available in the same series.

I first purchased a Miller Econtig back in the day and was able to work with that machine for 10 years. Originally costing $1200 and sold 10 years later for $800. I guarantee you I made more than $400 with that machine. It was kept clean and fetched a good resale (without cylinder).

These machines also stick weld (GMAW).

I seldom use my TIG, compared to the MIG, but its nice to have one in the arsenal. I can MIG weld very thin material including Aluminum but when working on funny cars, firearms and aircraft a TIG is required plain and simple. It requires special attention to tungsten selection and material prep. Takes twice as long and requires patience and practice. That said, welcome to the TIG world.

EDIT: Q&A

https://www.millerwelds.com/resources/article-library/choosing-a-tig-system-qa

Paco