-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which Quiet Air Compressor

- Thread starter cbrussell

- Start date

- Joined

- Jul 31, 2020

- Messages

- 765

I would mention the Paasche series of products again, which use far less air than most. They are geared to small and precise work.

- Joined

- Nov 15, 2016

- Messages

- 943

Two things I'd like to add are 1: The gun is the single biggest problem with most of the smaller blasters I've seen and 2: while volume is the most important factor with regards to air about 60 p.s.i. at the nozzle is the most you want to run with glass beads, 40-45 works fine. High pressure shatters the beads and also impinges the surface so hard that some glass gets embedded in the surface on softer materials especially on Aluminium.

I got a Kobalt Ultra Quiet 26 gal compressor last year. It is located within 10 feet of where I work. It is VERY quiet but does get a bit louder as the tank pressure builds. However, it is still whisper quiet compared to traditional compressors. I am very pleased with it. But I must say I don't work it very hard as I don't do blasting and have moved from pneumatic tools to battery powered.

- Joined

- Dec 13, 2016

- Messages

- 142

Well six years ago I start blasting with HF cabinet using a 20 gallon Craftman oilerless compressor. Enough said start researching air compressor and moisture issues. It is amazing to all the technics that people go through to get dry air.

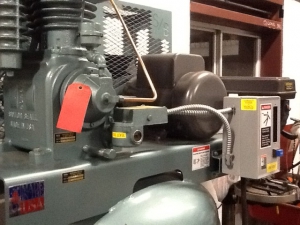

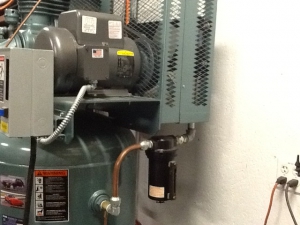

So my requirements were made in USA, quiet as possible, dry air, two-stage 150 psi, disc check valves and at least 80 vertical tank. Quiet compressor turn at lower rpms (500 to 900 rpm, have large pulley) with a 1725 rpm motor - think chug,chug,chug... Dry air with factory “after cooler” between the compressor discharge and the tank. Settled on two companies: Champion RV Advantage and Saylor-Beall VT-735-80 Full Package.

I went with Saylor-Beall because there aftercooler design Is more efficient since they have a fan attached to the motor pulley verse using cast fins on the compressor pulley. This is my most expensive single item investment in my shop. But it is a one time purchase for rest of my life. In the 60 hours run time (added an hour meter), only have few drops of moisture in my air lines. I added a Wilkerson water separator with an automatic drain between the aftercooler and the tank which capture probably 80% plus of moisture with tank automatic drain catch the rest. Never water on the floor.

Everything was made in USA except SquareD magnetic starter (Mex.) and some Chinese pipe fittings.

Bob G.

So my requirements were made in USA, quiet as possible, dry air, two-stage 150 psi, disc check valves and at least 80 vertical tank. Quiet compressor turn at lower rpms (500 to 900 rpm, have large pulley) with a 1725 rpm motor - think chug,chug,chug... Dry air with factory “after cooler” between the compressor discharge and the tank. Settled on two companies: Champion RV Advantage and Saylor-Beall VT-735-80 Full Package.

I went with Saylor-Beall because there aftercooler design Is more efficient since they have a fan attached to the motor pulley verse using cast fins on the compressor pulley. This is my most expensive single item investment in my shop. But it is a one time purchase for rest of my life. In the 60 hours run time (added an hour meter), only have few drops of moisture in my air lines. I added a Wilkerson water separator with an automatic drain between the aftercooler and the tank which capture probably 80% plus of moisture with tank automatic drain catch the rest. Never water on the floor.

Everything was made in USA except SquareD magnetic starter (Mex.) and some Chinese pipe fittings.

Bob G.

Attachments

-

9DB9F02B-D0FD-49B4-941E-43F1C0CA0385.jpeg176.8 KB · Views: 36

9DB9F02B-D0FD-49B4-941E-43F1C0CA0385.jpeg176.8 KB · Views: 36 -

EA6C40F6-5D94-49B5-AA49-F96FC5E64D2C.jpeg104 KB · Views: 35

EA6C40F6-5D94-49B5-AA49-F96FC5E64D2C.jpeg104 KB · Views: 35 -

E3F2F9FD-7A58-4F61-8B40-800AE74F65F4.jpeg186.6 KB · Views: 33

E3F2F9FD-7A58-4F61-8B40-800AE74F65F4.jpeg186.6 KB · Views: 33 -

1C9B0B22-6E22-4F5F-8EDC-D2720A3B9DBB.jpeg192.5 KB · Views: 32

1C9B0B22-6E22-4F5F-8EDC-D2720A3B9DBB.jpeg192.5 KB · Views: 32 -

483C40B0-9C46-4F93-B2D3-6E38D8E148DC.jpeg161.7 KB · Views: 32

483C40B0-9C46-4F93-B2D3-6E38D8E148DC.jpeg161.7 KB · Views: 32 -

C469FF6E-70B1-406E-8599-E0937EBF53A5.jpeg191.5 KB · Views: 33

C469FF6E-70B1-406E-8599-E0937EBF53A5.jpeg191.5 KB · Views: 33

Last edited:

- Joined

- Nov 26, 2017

- Messages

- 1,516

I am looking at the Kobalt Model #XC602000, 60 gallon vertical tank, 2 stage compressor, 3.7HP 230v motor. It is rated at 175 Maximum PSI and 6.9 SCFM at 175 PSI.

From what I have read they have a good rating overall. The one complaint is that you have to go over the fittings as they are often loose and leak. But with proper sealant, that can be corrected. The only other issue is the drain value under the tank is hard to access, but I have seen that on very expensive units.

From what I have read they have a good rating overall. The one complaint is that you have to go over the fittings as they are often loose and leak. But with proper sealant, that can be corrected. The only other issue is the drain value under the tank is hard to access, but I have seen that on very expensive units.

- Joined

- Dec 13, 2016

- Messages

- 142

I have a similar blast cabinet and it pretty much uses all the air my 5 HP, 220V 3 phase, 80 gal, compressor can produce. That is if I blast continuously the compressor will run continuously. If such a compressor is totally out of the question, you can gang together two smaller 120V compressors rated at 7 CFM each, will give you the required 14 CFM. However, they will have to be on separate circuits.

14 CFM is a lot of air for a small cabinet. Could use a smaller orifice nozzle to reduce air flow but still have velocity.