Hi there!

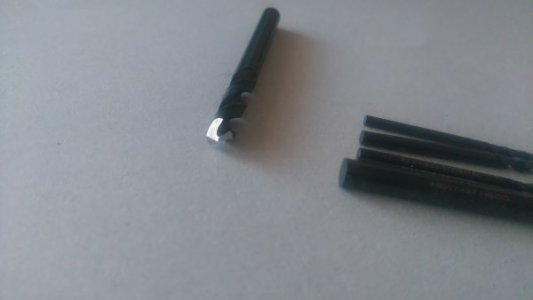

Ive got a few different set of drills.

I have a nice set (Cleeline) of Fractionals, Letter, and Number set which I'll keep as is for general use in aluminum/steel.

I'm looking to modify a set of fractional drills for use in only plastic and brass. I have a spare set of cleelines, or I can pick up a cheap set of fractionals for $30.

If im looking to make a set for brass/plastics, should I go ahead and modify my set of super nice cleelines? or should I just go get and modify a cheaper set of drills?

I'm not concerned with the job of modification itself, that will be fairly easy for me.

I actually already have a modified set of cleelines too, but im looking to make another brass/plastics set so i can have two, one to work in the garage and one to work in the house upstairs.

So given that I only have one spare set of nice drills, should I "use" these up to make a brass set, or so should I go ahead and purchase a cheaper set of drills, and save this set of cleelines for the future?

I suppose the real question is, when drilling with modified drills, how important is the drill bit quality?

i do notice a huge difference in drilling quality when cutting alu/steel with cheap bits VS with cleelines, but will the difference be as drastic when comparing two modified sets (one cheap and one being cleeline)? since the bits are scraping more than cutting?

Thanks!

Ive got a few different set of drills.

I have a nice set (Cleeline) of Fractionals, Letter, and Number set which I'll keep as is for general use in aluminum/steel.

I'm looking to modify a set of fractional drills for use in only plastic and brass. I have a spare set of cleelines, or I can pick up a cheap set of fractionals for $30.

If im looking to make a set for brass/plastics, should I go ahead and modify my set of super nice cleelines? or should I just go get and modify a cheaper set of drills?

I'm not concerned with the job of modification itself, that will be fairly easy for me.

I actually already have a modified set of cleelines too, but im looking to make another brass/plastics set so i can have two, one to work in the garage and one to work in the house upstairs.

So given that I only have one spare set of nice drills, should I "use" these up to make a brass set, or so should I go ahead and purchase a cheaper set of drills, and save this set of cleelines for the future?

I suppose the real question is, when drilling with modified drills, how important is the drill bit quality?

i do notice a huge difference in drilling quality when cutting alu/steel with cheap bits VS with cleelines, but will the difference be as drastic when comparing two modified sets (one cheap and one being cleeline)? since the bits are scraping more than cutting?

Thanks!