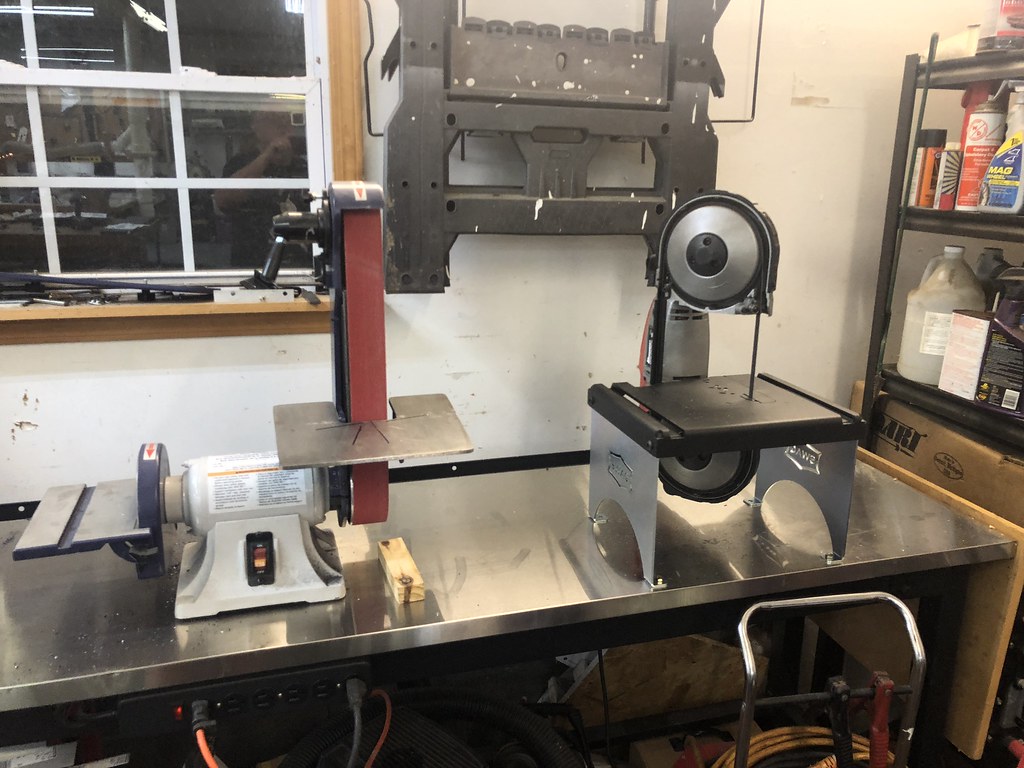

This is very interesting. I was wondering if you wouldnt mind pointing out the differences that you notice that you feel have improved it. My saw works but it could be better. The crooked cut gets to be a little annoying but I really dont think about it much as I automatically watch where the cut is going. I always think to myself that there are not any affordable metal band saws available and I can do most anything I want with this. I am very happy to have such a versatile tool. I use it all the time and have cut to its max depth on many many occassions and it performed very well.

I noticed recently that the top wheel is starting to get runout. I havent found a way to get rid of it though.

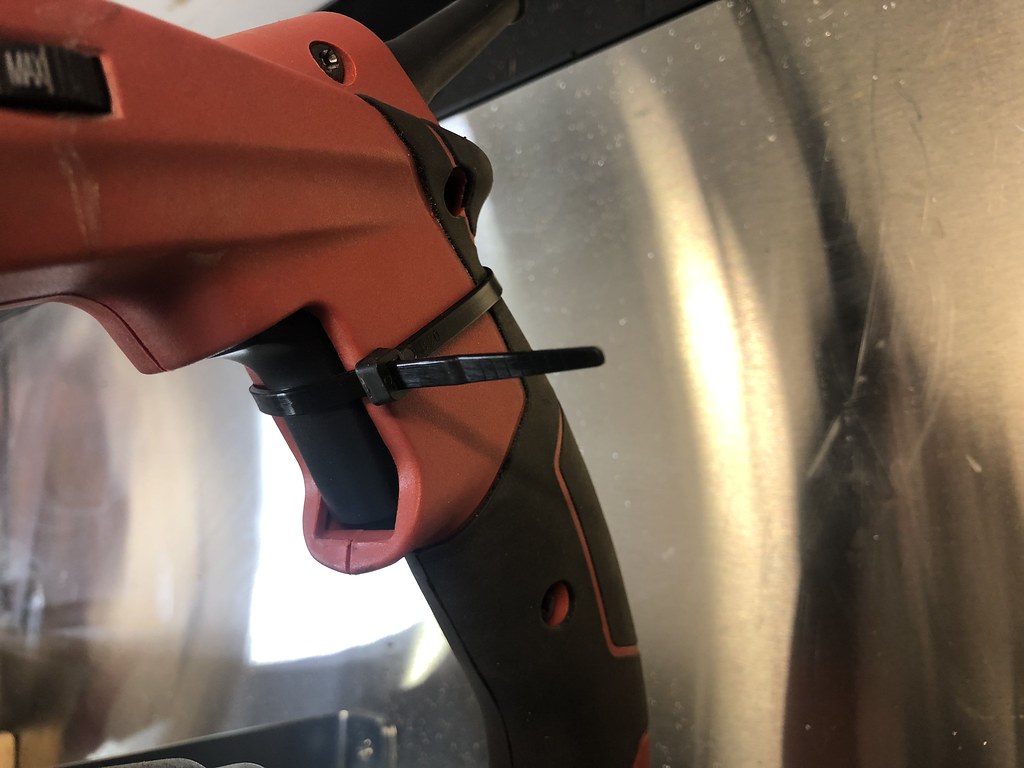

Oh, one quick suggestion. I am not sure how long your blades last before wearing out or breaking but the best way to make a blade last without breaking is to release the tensioner after you are done using it. In 2 years I have gone through 5 blades. 2 were El Cheapo’s from HF and the other 3 were Milwaukee. I have only broke one blade and that was because a few teeth got ripped off of it and it grabbed into a part I was cutting off. I am still using one of the remaining 3 name brand blades. The other 2 name brand blades wore out but have never broke. Releasing the tension allows the band to relax and prolongs its life. It is recommended t do this with all bandsaws but unfortunatly its not practical to do this with most machines. The portabands are the exception.

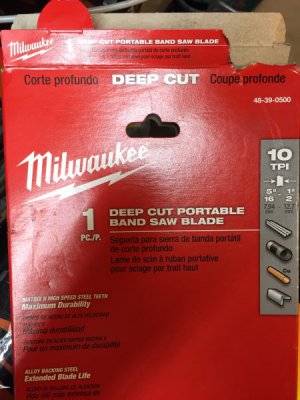

Lastly, I found a blade that I highly recommend for these portable bandsaws. Its a Milwaukee 10tpi Deep Cut. I have cut plastic aluminum steel brass in all different shapes and sizes. The tooth count and blade angle has been very universal to any material and material thickness. I never change it out. Just thought this bit of info would help anyone with one of these. Oh, and they are cheap. My local family owned hardware store which isnt cheap sells these for $9. Here is a picture of the box.

View attachment 274352