May or may not be your problem but when bearings are going, the readings will repeat every other rotation. This is because the bearings rotate around the spindle half as fast as the spindle rotates.

Some real good detective work in this post. I would never have known to even think of this issue.

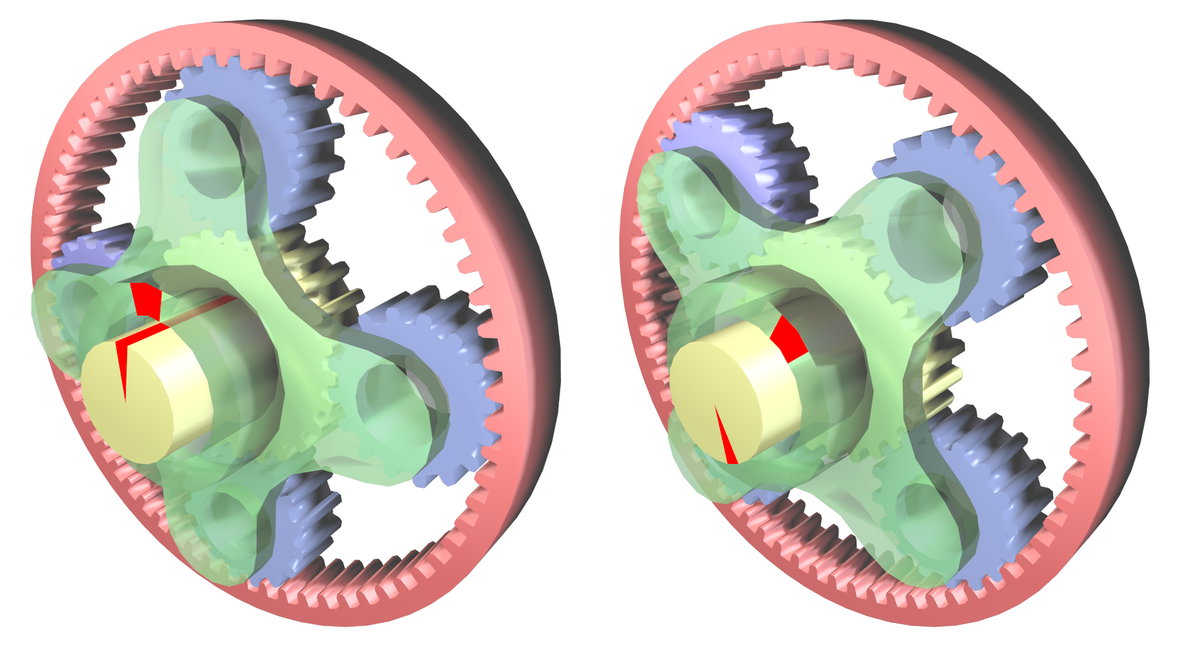

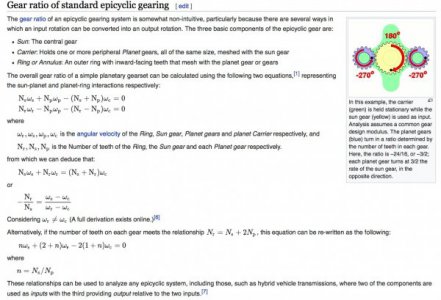

I'm trying to wrap my brain around the 2nd rotation reading thing. Are you saying for example a cluster of rolling elements are worn, therefore a bit more annular gap between rings. So if that cluster was phased at the 3-o'clock position you could measure runout in that position. But now at 1 full spindle rotation the bearings would only have migrated to 9-o'clock. Wouldn't this 2:1 relationship be a function of the rolling element diameter kind of like idler gears? ie smaller diameter rolling element take longer to migrate than larger ones?