-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Win. 1886 takedown conversion questions

- Thread starter Mike8623

- Start date

- Joined

- Apr 23, 2018

- Messages

- 6,508

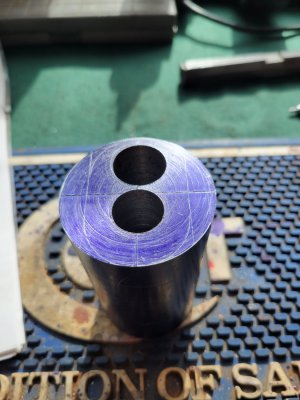

I've been working on my takedown extensions. Just have to machine the sides a bit to get in my mill straight, then mill the insides a bit then work on the outsides. Mag tubes should be here today.

We'll see how it goes.

We'll see how it goes.

Attachments

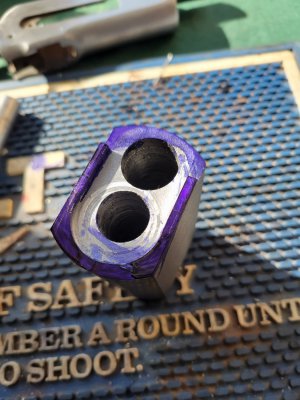

Well progressing along. Gonna take those 4 corners off, thinking about that raised divot on the receiver and the recession for it on the takedown plate......but it is all coming along.

Attachments

Thanks for the advice. I'm trying to keep it a rectangle as long as possible so that I can get a good grip in my mill.

What do you think bout that divot. Shape, size, force application etc etc.

What do you think bout that divot. Shape, size, force application etc etc.

Attachments

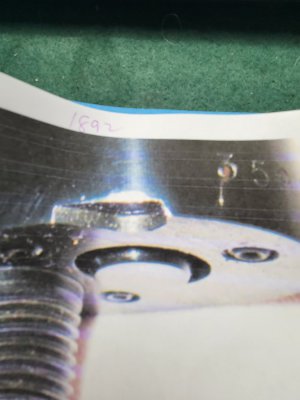

So the height must be one turn of the threads high...... .050 inch. I'll think bout it tonight before going to sleep. I plan most my day while in bed and before i go to sleep the night before. The takedown extension part will be easy, gotta think how I'll do the counterpart on the receiver.

- Joined

- Jan 28, 2011

- Messages

- 3,480

They are the positive stop. So fitment is important. I made the bump fit the divot, as it is easier to remove a small amount at a time then weld in more. Yes you need one turn to clear and a couple thousandths additional as the block has not made a full revolution until it passes the bump, so the bump is less than the .050”. It has no bearing on recoil fortunately.

Pierre

Pierre