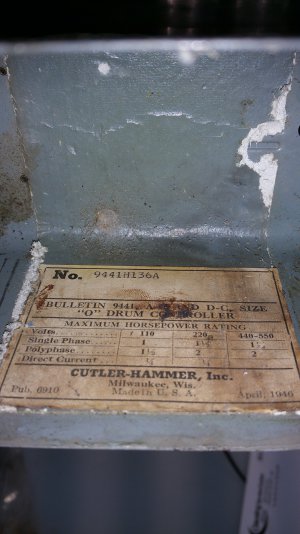

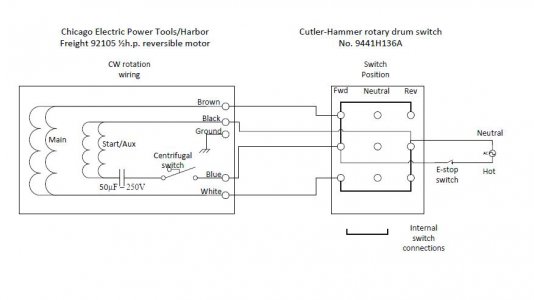

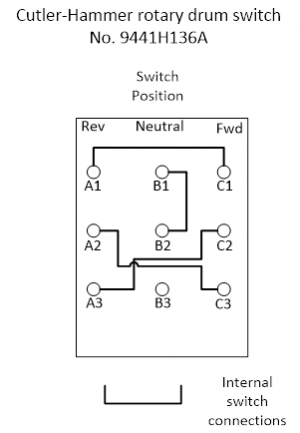

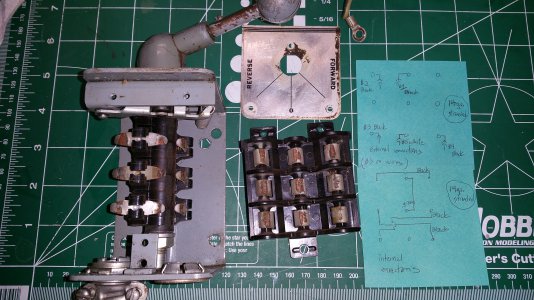

not too many threads with the chinese 4 wire motors, but after much perusing, some videos and articles, I've managed to create the below diagram to wire the motor that came with my little Craftsman 101, and a vintage rotary switch that is also 115V single phase capable.

Im pretty sure Im missing some things, but this is as far as I could get over the weekend.

some basics for the effort

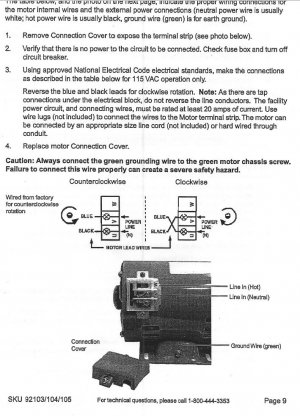

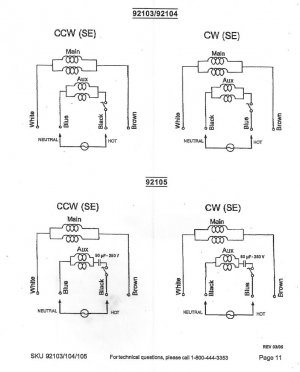

Motor is a Chicago Electric Power Tools (Harbor Freight) 92105 motor

115VAC, 60Hz, single phase 1/2hp reversible motor (CCW on facing shaft)

5amp no load, 7.54amp peak, 1725rpm

NEMA 48, 5/8" shaft

Four poles fan cooled, centrifugal switch, capacitor start

Im pretty sure Im missing some things, but this is as far as I could get over the weekend.

some basics for the effort

Motor is a Chicago Electric Power Tools (Harbor Freight) 92105 motor

115VAC, 60Hz, single phase 1/2hp reversible motor (CCW on facing shaft)

5amp no load, 7.54amp peak, 1725rpm

NEMA 48, 5/8" shaft

Four poles fan cooled, centrifugal switch, capacitor start