- Joined

- Feb 8, 2014

- Messages

- 11,144

A customer asked me to build a press to form a 4 inch diameter x 1/8 inch thick split disk into helix. So having a few log splitters on the shelf, that seem like a good starting point.

Here is one kind of like what I started with, just a different wheel arrangement

And the under side. These have reasonably robust hydraulics.

First the support plates for the platen, 16 1/2 x 12 x3/4 inch thick A36 plate. This will become the two supports. That's a big ugly thing to be working on in the mill. Getting ready to drill the mounting holes. 3/4'' MDF under as a spoil board.

Getting ready to drill the mounting holes. 3/4'' MDF under as a spoil board.

All bolted down and chewing through the first cut with a 1/2'' rougher. 0.375 DOC, 680 RPM, 2 IPM.

And chewing through the platen. 5/8 A36 plate. I went an inch deep in this one to get into the unused part of the end mill, so 3/8'' of the end mill was cutting MDF. One pass at 2 IPM, 680 RPM.

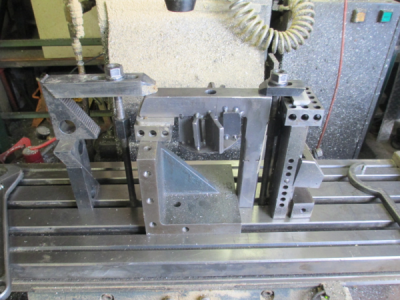

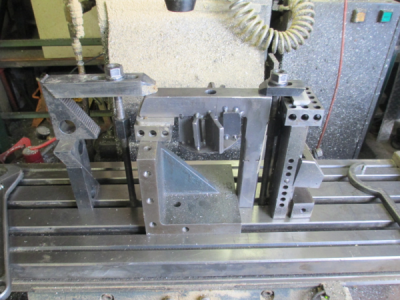

One of the more interesting setups I have done. Stack up anything that works. This is the bottom of the customer supplied forming die. I needed to drill & tap a couple of mounting holes in it. This was the only way I could come up with to hang on to it.

This is the bottom of the customer supplied forming die. I needed to drill & tap a couple of mounting holes in it. This was the only way I could come up with to hang on to it.

And the holes drilled & tapped. This is an interesting die. The customer made this, it's all a weldment. It looks crude, but works well and is actually a nice design. I'll show some pictures of this later.

This is all I have for now.....stay tuned for more.

Here is one kind of like what I started with, just a different wheel arrangement

And the under side. These have reasonably robust hydraulics.

First the support plates for the platen, 16 1/2 x 12 x3/4 inch thick A36 plate. This will become the two supports. That's a big ugly thing to be working on in the mill.

All bolted down and chewing through the first cut with a 1/2'' rougher. 0.375 DOC, 680 RPM, 2 IPM.

And chewing through the platen. 5/8 A36 plate. I went an inch deep in this one to get into the unused part of the end mill, so 3/8'' of the end mill was cutting MDF. One pass at 2 IPM, 680 RPM.

One of the more interesting setups I have done. Stack up anything that works.

This is the bottom of the customer supplied forming die. I needed to drill & tap a couple of mounting holes in it. This was the only way I could come up with to hang on to it.

This is the bottom of the customer supplied forming die. I needed to drill & tap a couple of mounting holes in it. This was the only way I could come up with to hang on to it.

And the holes drilled & tapped. This is an interesting die. The customer made this, it's all a weldment. It looks crude, but works well and is actually a nice design. I'll show some pictures of this later.

This is all I have for now.....stay tuned for more.