- Joined

- Jan 28, 2018

- Messages

- 10

I picked up a VN 1/2 mill from Craigslist last month. It's 100ish years old, and it's a pretty neat little machine. It's dirty, and needs to have the cobwebs blown out of it, but I've been biting off little chunks of the restoration project each week, and it's starting to come together. I don't care for aesthetics much at this point, I just want to get it functional and start learning about machining.

The motor is a 3-phase Lima motor with a gearbox, mounted up top. The other photos that I've seen of these machines have the motor mounted down low, and transfer power through a series of belts and pulleys to a bevel gear that turns the corner and actually drives the spindle. The setup on my machine is much simpler than that, although I wish it was mounted sideways and still had the 90deg gear to turn the corner and provide a bit more clearance over the bed.

I got it wired up a few weeks ago, and made my first chips. Since then I've been doing recon on the different systems. I replaced 2 of the pivot bolts on the spindle head because one of them was broken (and they had to match ) and last week I oiled the ways and freed up all of the sliding mechanisms. Luckily, there was nice shiny metal hiding on the ways, so she ought to slide nice and smooth without a lot of effort. I need to learn a bit about how to properly adjust the gibs, and then I'll try some more cuts.

) and last week I oiled the ways and freed up all of the sliding mechanisms. Luckily, there was nice shiny metal hiding on the ways, so she ought to slide nice and smooth without a lot of effort. I need to learn a bit about how to properly adjust the gibs, and then I'll try some more cuts.

For tooling, this machine uses "type C" collets, which are functionally the same as Hardinge 5V tapers. I snagged a 5/8" collet on Amazon (for a very good price compared to what they've been marked up to, since) and my plan is to chuck up a straight shank 5/8" ER20 collet holder. It's not 100% ideal, but it puts a cheap, replaceable part between the spindle and the work while I learn, and it's a pretty affordable way to buy collets. I also found a face mill arbor on ebay, so that's on its way, too.

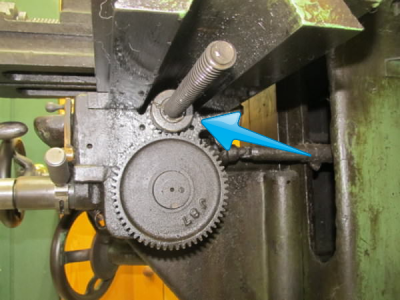

One of the next mysteries that I need to solve is the bed feed mechanism. Most of the mechanicals are gone (there was originally a driveshaft with a UV joint that drove a worm gear on the bed's leadnut) but the worm wheel and mechanism under the table is still there. I couldn't spin it by hand, but I'm going to douse it with penetrating oil this week and see if I can break it loose with a strap wrench enough to work new grease into it and get it spinning nicely.

I've been documenting my journey on my local makerspace's forum but I figured that posting some of the highlights here would also be useful to folks.

Does anybody else have one of these machines? I get the impression that there aren't very many of them out there.

Thanks for reading!

The motor is a 3-phase Lima motor with a gearbox, mounted up top. The other photos that I've seen of these machines have the motor mounted down low, and transfer power through a series of belts and pulleys to a bevel gear that turns the corner and actually drives the spindle. The setup on my machine is much simpler than that, although I wish it was mounted sideways and still had the 90deg gear to turn the corner and provide a bit more clearance over the bed.

I got it wired up a few weeks ago, and made my first chips. Since then I've been doing recon on the different systems. I replaced 2 of the pivot bolts on the spindle head because one of them was broken (and they had to match

For tooling, this machine uses "type C" collets, which are functionally the same as Hardinge 5V tapers. I snagged a 5/8" collet on Amazon (for a very good price compared to what they've been marked up to, since) and my plan is to chuck up a straight shank 5/8" ER20 collet holder. It's not 100% ideal, but it puts a cheap, replaceable part between the spindle and the work while I learn, and it's a pretty affordable way to buy collets. I also found a face mill arbor on ebay, so that's on its way, too.

One of the next mysteries that I need to solve is the bed feed mechanism. Most of the mechanicals are gone (there was originally a driveshaft with a UV joint that drove a worm gear on the bed's leadnut) but the worm wheel and mechanism under the table is still there. I couldn't spin it by hand, but I'm going to douse it with penetrating oil this week and see if I can break it loose with a strap wrench enough to work new grease into it and get it spinning nicely.

I've been documenting my journey on my local makerspace's forum but I figured that posting some of the highlights here would also be useful to folks.

Does anybody else have one of these machines? I get the impression that there aren't very many of them out there.

Thanks for reading!