- Joined

- Aug 20, 2018

- Messages

- 219

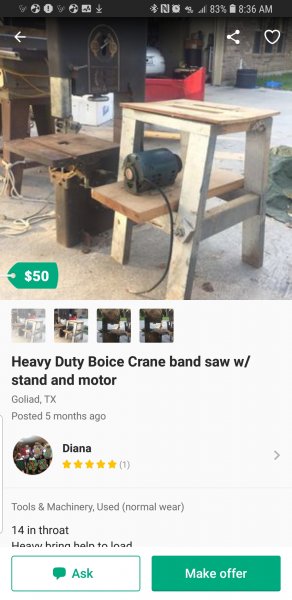

I'm looking for a metal cutting bandsaw, that doesnt break the bank. I came across this one, but I'm not sure if it will do the job or not. Any info/ideas would be greatly appreciated.

Also, anyone have any experience with HF horizontal bandsaw? Thanks I'm advance guys, you all always give me good info.

Also, anyone have any experience with HF horizontal bandsaw? Thanks I'm advance guys, you all always give me good info.