- Joined

- Oct 6, 2010

- Messages

- 699

Not exactly a “classic car, plane train helicopter or rocket” but this seemed like the most likely forum to place a project like this. I found this Taylor Dunn “Burden Carrier” setting in the scrap yard and I saw it being handy around the home place so I adopted it.

Made an arrangement with the scrap yard manager to weight it and return the unwanted pieces not needed for the home project I had in my head. This saved me the cost of 350 pounds of scrap I did not need or want.

My thoughts on the project were to get rid of the solid rubber covered cast iron wheels and electric motor drive. The vehicle still has the solid wheels in the photo above before any pneumatic tires and wheels could be located. My first thoughts were to place a hydrostatic lawn tractor engine and drive train under it. This would make the wife “want to help around the yard”. She loves to drive the zero turn mower!

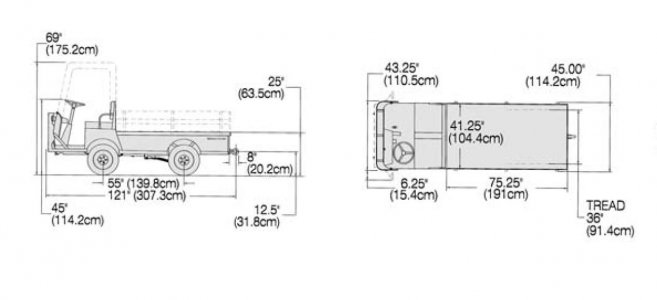

I know the thing looks bad in the photo above but this photo from the Taylor Dunn site is my inspiration:

I do not plan to use the safety yellow color shown in the photos when I get to the point of new paint. First goal is to get it moveable under its own power.

Has anyone done a project like this or have any ideas. My idea of the lawn tractor power train seems easy but I suspect getting the controls to the cab area may not be so simple!

More to come as parts and photos become available. There should be some machining and fabrication content before this is over with.

Benny

The Orphanage Never Closes

Made an arrangement with the scrap yard manager to weight it and return the unwanted pieces not needed for the home project I had in my head. This saved me the cost of 350 pounds of scrap I did not need or want.

My thoughts on the project were to get rid of the solid rubber covered cast iron wheels and electric motor drive. The vehicle still has the solid wheels in the photo above before any pneumatic tires and wheels could be located. My first thoughts were to place a hydrostatic lawn tractor engine and drive train under it. This would make the wife “want to help around the yard”. She loves to drive the zero turn mower!

I know the thing looks bad in the photo above but this photo from the Taylor Dunn site is my inspiration:

I do not plan to use the safety yellow color shown in the photos when I get to the point of new paint. First goal is to get it moveable under its own power.

Has anyone done a project like this or have any ideas. My idea of the lawn tractor power train seems easy but I suspect getting the controls to the cab area may not be so simple!

More to come as parts and photos become available. There should be some machining and fabrication content before this is over with.

Benny

The Orphanage Never Closes