- Joined

- May 2, 2018

- Messages

- 144

I didn't want to hijack another thread about DIY Demagnetizers so I started this one.

Every once in awhile I have an idea that actually works.

One thing that I find annoying is tools that become magnetized for one reason or another.

Screwdrivers, Pliers, Drill Bits, etc. …

I wanted a simple CHEAP demagnetizer.

All I needed was a magnetic core, a coil and an AC voltage.

Here is what I came up with.

I used a motor from a fan.

The one I actually used is from an old microwave oven.

The one in the pictures is from a bathroom exhaust fan but is identical.

I simply removed the rotor assembly and the core copper (optional).

I hooked up a momentary pushbutton switch and a pilot light (optional) and a power cord.

I used a polarized cord and put the pushbutton switch in the hot side of the power cord.

I mounted it into a plastic box and that was it.

IT WORKS GREAT.

To use it, energize the demagnetizer.

Bring the object to demagnetize to the demagnetizer.

It is OK to let the object come in contact with the demagnetizer.

Withdraw the object from the demagnetizer at least 12” before de-energizing the demagnetizer.

This will prevent accidently re-magnetizing the object.

I have demagnetized screwdrivers, pliers, drill bits in a matter of seconds.

I even completely demagnetized a Model T flywheel magnet.

It is small enough to be handheld so you can bring the demagnetizer to the object.

Words of caution :

Use a momentary pushbutton switch only.

Make sure the motor you use is rated for the same voltage you plug the device into.

Make sure all electrical connections are solid and safe for the operator.

Be_Zero_Be

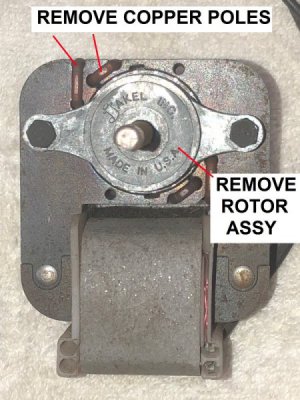

Photo-1

Fan motor salvaged from an old bathroom fan.

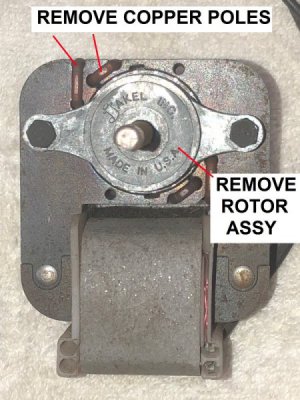

Photo-2

Make these modifications to the motor.

Photo-3

Cut the pole piece as shown.

Be careful not to damage the windings.

Photo – 4

The final product with momentary push button and optional pilot light.

Every once in awhile I have an idea that actually works.

One thing that I find annoying is tools that become magnetized for one reason or another.

Screwdrivers, Pliers, Drill Bits, etc. …

I wanted a simple CHEAP demagnetizer.

All I needed was a magnetic core, a coil and an AC voltage.

Here is what I came up with.

I used a motor from a fan.

The one I actually used is from an old microwave oven.

The one in the pictures is from a bathroom exhaust fan but is identical.

I simply removed the rotor assembly and the core copper (optional).

I hooked up a momentary pushbutton switch and a pilot light (optional) and a power cord.

I used a polarized cord and put the pushbutton switch in the hot side of the power cord.

I mounted it into a plastic box and that was it.

IT WORKS GREAT.

To use it, energize the demagnetizer.

Bring the object to demagnetize to the demagnetizer.

It is OK to let the object come in contact with the demagnetizer.

Withdraw the object from the demagnetizer at least 12” before de-energizing the demagnetizer.

This will prevent accidently re-magnetizing the object.

I have demagnetized screwdrivers, pliers, drill bits in a matter of seconds.

I even completely demagnetized a Model T flywheel magnet.

It is small enough to be handheld so you can bring the demagnetizer to the object.

Words of caution :

Use a momentary pushbutton switch only.

Make sure the motor you use is rated for the same voltage you plug the device into.

Make sure all electrical connections are solid and safe for the operator.

Be_Zero_Be

Photo-1

Fan motor salvaged from an old bathroom fan.

Photo-2

Make these modifications to the motor.

Photo-3

Cut the pole piece as shown.

Be careful not to damage the windings.

Photo – 4

The final product with momentary push button and optional pilot light.