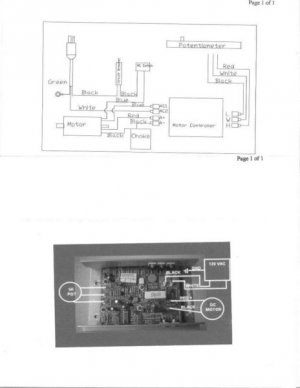

For a belt grinder, got it all reconnected and working with the original display....my question for all the electrictronic magicians is this:

For a belt grinder, got it all reconnected and working with the original display....my question for all the electrictronic magicians is this:Where in this godforsaken mess could I connect a pot dial and an on off switch to do away with the monster sized digital display and controls? The wide paddle connection is the one from the control panel....was hoping there was an easier way than cutting that open and using trial and error....