- Joined

- Oct 18, 2016

- Messages

- 2,872

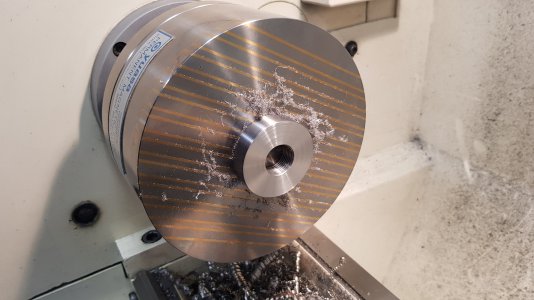

Have fun cleaning up all the cast iron. I still haven't gotten around to mounting my chuck; must be a subliminal wish to avoid clean up!

Mike, have you ever tried attaching your shop vac hose to the tool post? Tape, cable ties, whatever will work and it sends about

95 percent of the chips right down the hose.