- Joined

- Feb 2, 2013

- Messages

- 3,622

My good ol' Shenwai SW900B is showing signs of excessive slop at the dial.

excessive slop for me is right around .050"

after pondering materials to construct a new nut from, delrin was immediately apparent.

its tough and structurally sound, it's easy to get and cheaper than other materials too.

so delrin it is!!!

i procured some 1-1/4" black delrin and planed the billet to usable dimensions on my Ammco 7" shaper

here is video of the planing operation:

after planing the billet,

i cut off a slightly larger than necessary piece and reduced it to final dimensions on the shaper, using a simple round nose grind.

the OEM nut is constructed from bronze ans is very rectangular in shape, with rounded corners.

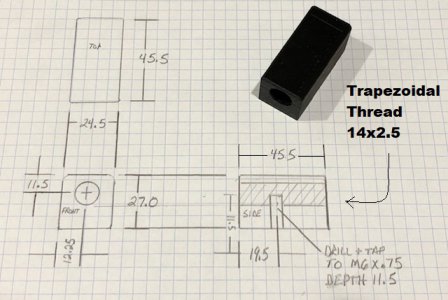

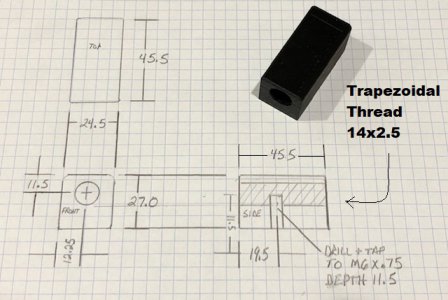

i copied the dimensions to the millimeter and transposed the centerlines of the longitudinal axis and a transverse drilling for the nut retaining bolt

i special ground a HSS bit for the corner rounding operation and went to town on the nut

after cutting the profile on one side to satisfaction, i flipped the part in the vise and reacquired zero,

then matched the radius with the cut before

after i finished the blank, i punched and drilled the blank- then tapped the left hand trapezoidal threads.

there is zero backlash between the leadscrew and the delrin nut, but the leadscrew can be turned with very little effort- YIPPEEE!!!!!

i then drilled and tapped the retainer bolt to M6, to reuse the OEM bolt.

Only after completing the nut, did i transpose the dimensions to paper.

without further adieu, my version of the LH trapezoidal thread cross slide nut!

i'll be installing soon!

stand by-

same bat station, different bat time!

excessive slop for me is right around .050"

after pondering materials to construct a new nut from, delrin was immediately apparent.

its tough and structurally sound, it's easy to get and cheaper than other materials too.

so delrin it is!!!

i procured some 1-1/4" black delrin and planed the billet to usable dimensions on my Ammco 7" shaper

here is video of the planing operation:

after planing the billet,

i cut off a slightly larger than necessary piece and reduced it to final dimensions on the shaper, using a simple round nose grind.

the OEM nut is constructed from bronze ans is very rectangular in shape, with rounded corners.

i copied the dimensions to the millimeter and transposed the centerlines of the longitudinal axis and a transverse drilling for the nut retaining bolt

i special ground a HSS bit for the corner rounding operation and went to town on the nut

after cutting the profile on one side to satisfaction, i flipped the part in the vise and reacquired zero,

then matched the radius with the cut before

after i finished the blank, i punched and drilled the blank- then tapped the left hand trapezoidal threads.

there is zero backlash between the leadscrew and the delrin nut, but the leadscrew can be turned with very little effort- YIPPEEE!!!!!

i then drilled and tapped the retainer bolt to M6, to reuse the OEM bolt.

Only after completing the nut, did i transpose the dimensions to paper.

without further adieu, my version of the LH trapezoidal thread cross slide nut!

i'll be installing soon!

stand by-

same bat station, different bat time!