- Joined

- Mar 30, 2024

- Messages

- 21

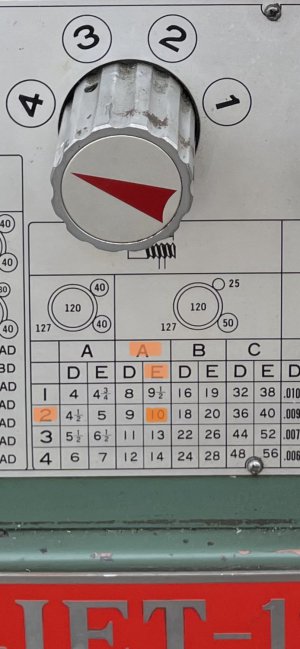

@David2011 wow thank you for explaining that to me. That’s enough for me to understand what’s going on and how to get started.

First time I flipped through the owner manual I was just lost and couldn’t make sense of any of it. Breaking it down and drawing attention to specific content really helps organize my squirrels.

First time I flipped through the owner manual I was just lost and couldn’t make sense of any of it. Breaking it down and drawing attention to specific content really helps organize my squirrels.