- Joined

- May 7, 2023

- Messages

- 2,094

They are too small to be Blanchard ground - unless these are Blanchard ground flat, then sawn to size.... (possible, but a costly way to do it)

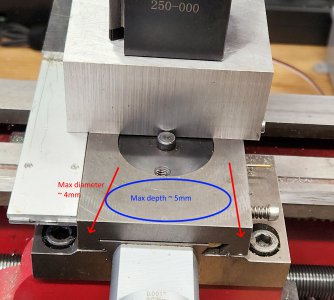

Do you have a piece of float glass or surface plate (countertop granite won't do). Then put a sheet of 2000 wet and dry on the flat surface and lightly take off the saw/grinding marks. This will improve your contact significantly. Only take a tiny bit off the tops of the marks until you see a new surface over most (75-80%) of the surface.

When/if you learn scraping, the same principle applies.

That is exactly the way they do it.

Small billets of oversize material ganged in rows and ground to size, then run through an automatic saw.

I do agree grinding and cutting these out of a large sheet of billet would be expensive, but these can be cut and put on a shelf ready to be shipped.

Making them in batches for ready use offsets the cost of paying the bank for having it sitting on the shelf.

Then you only need a guy to run the saw all day and others to pick/pack.

Materials cut to order will call out a lead time in the description.

Last edited: