- Joined

- Feb 8, 2014

- Messages

- 11,176

I am bidding a job of 750 pieces. Material 2 x 2 x 0.250 wall, square, structural steel tubing (A36?). The customer is specifying the material, I have no say in that.

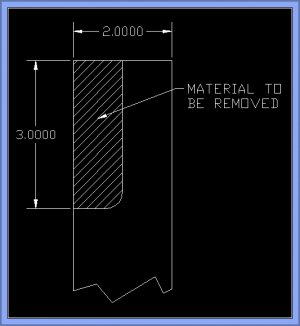

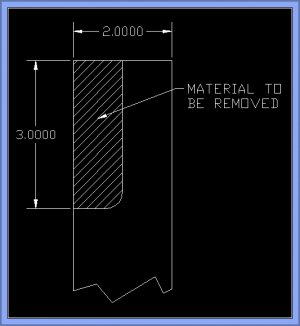

Machining: Cut a notch about 3 inches along the length and about an inch deep into the width, though both sides of the tube.

Because of the radius in the corner, I will be using a 5/8 TiN coated, cobalt rougher. The feed & speed will be optimized for the job, and I'll be using a heavy mist coolant. The total length of cut is about 5 inches per piece, and I'll do it in one pass.

The question is: How many pieces can I cut before the end mill is toast?

I need to order enough end mills to do the job, and of course estimate my tooling cost. At $36 each the tooling cost will be substantial. I'm guessing I can get about 30 pieces (about 150 cut inches total, or about 150 minutes), but some of you production guys have a lot more experience at this kind of thing than I do. Any ideas?

Machining: Cut a notch about 3 inches along the length and about an inch deep into the width, though both sides of the tube.

Because of the radius in the corner, I will be using a 5/8 TiN coated, cobalt rougher. The feed & speed will be optimized for the job, and I'll be using a heavy mist coolant. The total length of cut is about 5 inches per piece, and I'll do it in one pass.

The question is: How many pieces can I cut before the end mill is toast?

I need to order enough end mills to do the job, and of course estimate my tooling cost. At $36 each the tooling cost will be substantial. I'm guessing I can get about 30 pieces (about 150 cut inches total, or about 150 minutes), but some of you production guys have a lot more experience at this kind of thing than I do. Any ideas?

The neighbors barbecue up some great steaks and hamburgers.! We just kinda do stuff for each other. If I get this job, I'll post the actual run times.

The neighbors barbecue up some great steaks and hamburgers.! We just kinda do stuff for each other. If I get this job, I'll post the actual run times.