- Joined

- Oct 31, 2015

- Messages

- 468

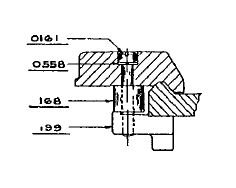

Those parts look just like mine. If the gib wasn't parallel to the bottom surface of the ways, then it wasn't assembled correctly. I wish I had a photo of mine to post, but I neglected to take any of that part of the assembly/disassembly process.