A friend had fitted some wheels from a different model to his motorcycle. The width of the hub was 5mm less so he needed 2.5mm thick spacers made up to go between the hub and the brake disc carriers on either side.

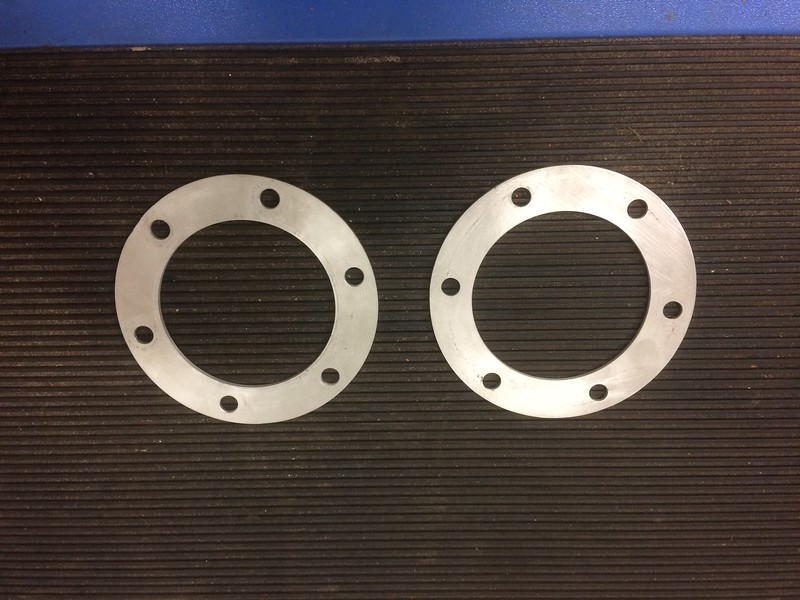

There were two of these spacers from his original wheel that he gave me to reduce the thickness from ~7.6mm to 2.5mm and open up the internal diameter from ~73mm to 80mm, removing the boss.

I skimmed the plain face.

flipped it around and secured it with some some copper shims on the inside bore.

reduced the thickness to 2.5mm and carefully started removing the centre boss.

and did the same to the other item.

Then I had to work out how to hold the pieces to bore the internal diameter out to 80mm.

The first cunning plan didn't work, with the piece ending up on the other side of the shop.

This was Plan B. I clamped both pieces onto a brake disc carrier.

and then mounted the brake disc carrier onto the chuck.

and bored the internal diameter.

some deburring and tidy up and the job was done.

pete