-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Edwards Radial 5 build thread --- PHOTOS!

- Thread starter JRaut

- Start date

- Joined

- Apr 29, 2019

- Messages

- 2,244

If this works out I may have to try one to. I already have an airplane to put it on. This is way beyond any project I have done to date. I love it, keep up the reports.

Good luck with the broken tap.

Good luck with the broken tap.

Looking good, following along. I'm building an Ohrndorf 5-cyl radial. Quite similar to the Edwards dimensions & overall layout (and my first go at anything this complex). I also broke a tap in my 2024 crankcase size M3, my own fault. The alum solution didn't work well at all. My conclusion on succes related to this is 'it kind of depends'. Mine was a coated tap as opposed to bright HSS which may have had something to do with it. It made a complete mess of the part long before the tap dissolved. Personally I would try & drill past it with a mini annular cutter, tap the hole & insert an aluminum plug permanently with Loctite & go from there. If you want to read about my grizzly details I can link my post over on Home Model Engine Machinist. There have been a few Edwards builds documented there btw if weren't already aware.

Last edited:

- Joined

- Aug 22, 2012

- Messages

- 4,254

try one of these, the simple one work great if a bit slow. Its saved me a heap of times

https://www.hobby-machinist.com/threads/tumbler-reverse.10122/ from post 19

https://www.hobby-machinist.com/threads/tumbler-reverse.10122/ from post 19

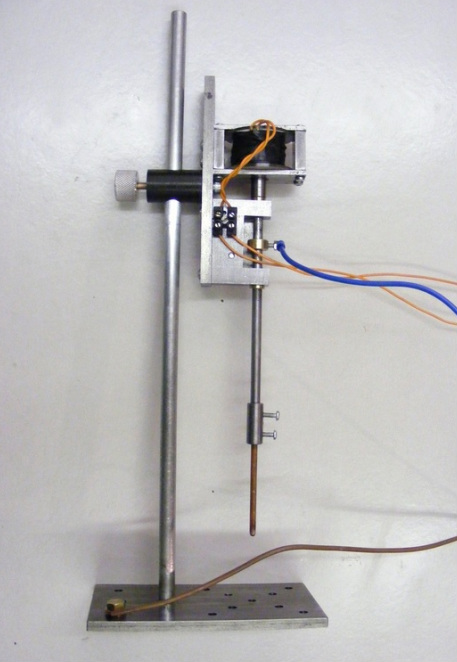

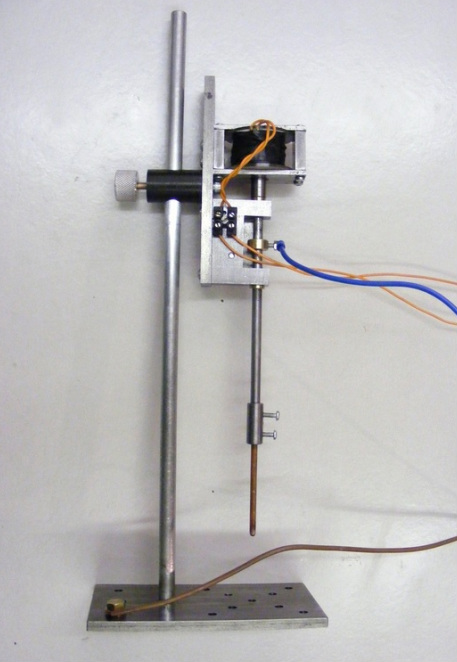

A spark erosion apparatus

Ever since I broke a tap whilst making the Improved chuck for taps I have been thinking of making a simple spark erosion apparatus. When making the hexagonal hole in the mill quill lock lever I again...

mikesworkshop.weebly.com

Unbelievable!

Outstanding achievement.

I agree, waaaaay over my head but I'm going to have fun trying to follow along.

- Joined

- Mar 26, 2018

- Messages

- 2,725

- Joined

- Mar 9, 2018

- Messages

- 468

***Spoiler alert***

I did this all a couple weeks ago and am just now catching up with writing about it.

I tried using the 'dissolving it in an Alum solution' method with absolutely zero success. Worse, actually.

Hopefully I'll have some time today to write up a more detailed post on the topic.

*****************

I did this all a couple weeks ago and am just now catching up with writing about it.

I tried using the 'dissolving it in an Alum solution' method with absolutely zero success. Worse, actually.

Hopefully I'll have some time today to write up a more detailed post on the topic.

*****************