I never thought of putting steel strips alongside the lathe to attach the indicator stand to. I've just relied on the weight of the stand to keep it in place, which luckily on projects that fit the Sherline has been adequate if occasionally frustrating.

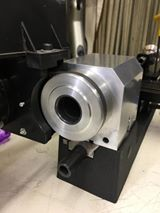

It looks like you have the extended tool post and riser blocks?

I do have the riser kits. For small work, I don’t use them, but I’ve dialed in the tailstock with the riser blocks installed, so anything that requires centers or drilling work, it goes on the blocks.

I brazed on a wrench and it slides in and out nicely on it as well.

The steel strip is a pice of 3’ from the big box store of choice. Drill and countersink some holes and attach. I haven’t found much use for a strip in the front (but then, I haven’t used one in the front!). Most of my indicator work is either from the backside or top...

As I mentioned, next version, i’m hoping to put the lathe bed on risers to get more room between the lathe and base (give more room for indicators, larger handwheels, etc)

Brad