- Joined

- May 2, 2021

- Messages

- 330

New to forum & machining generally.

Working on two stroke motors drove my initial interest to learn.

Started searching for a Bridgeport...

Next thing I knew - I was standing outside a barn, 2 hours from my house, looking at a 4K lb non working CNC Webb knee mill.

More about how I got there and this project in a moment - but first - a big thank you to Jim Dawson, who has been stellar in helping me get some basics in CNC. Let's just say, uncommonly patient...

Some pics and discussion here: https://www.hobby-machinist.com/thr...ted-to-cnc-for-sale.92613/page-11#post-856335

So - about the project.

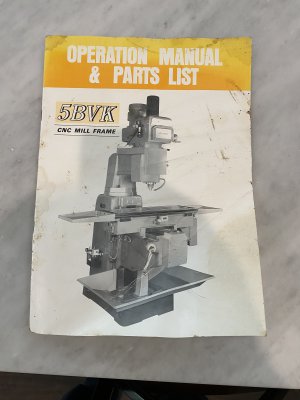

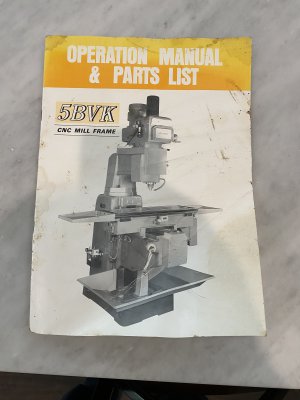

I've been offered a Webb 5BVK mill from 1989.

For those unfamiliar with this thing - Its basically a Bridgeport. On steroids. Lots and lots of steroids.

4000 lbs and boxed ways.

It came from the factory as a CNC, and was loaded with the goodies of that time.

Power draw bar, automated self oil, lubrication and pan, DC brushed servo motors, 5HP spindle drive.

At first glance, a non operational 5BVK might seem like, well, a terrible place to start for a garage based machine.

1. It could take up half that garage

2. Being able to work on it is 2x harder when everything weighs 2x...

3. It is CNC only, and the CNC doesn't work. Literally there are no handles or places for them.

4-10. Fill in the blank. It's old, smells like cutting oil, and is covered in a layer of oily dust and nastiness.

With that said, there are a couple things that have kinda drawn me in.

1. While this beast is about 6 feet wide, the table is a moderate 42 x 13. Kinda perfect.

2. Without David Hasselhof's 1980's Night Rider boxes hanging off the side - its kinda a handsome and literally half as wide.

3. If I could figure out how to add handles - it would create a manual mill for me with opportunity to go full CNC in Phase II.

4-10. The price is: Free. (kinda buried the lead I suppose on that one).

My basic plan is to tackle this in two phases.

I. Get it cleaned up and operational as a manual. See how I like it and if it has any fatal flaws.

II. Take it CNC - with the ability to use manually as well. DC brushed motors will help allow nice tactile manual feel here (Again - Jim Dawson's input invaluable).

I am completely green with these machines and their use - but I figure learning HOW it operates before I try and OPERATE it is a pretty good base.

Pictures below of this beast (*outside for about 30 days, Im told...)

No significant rust to speak of - surface stuff at worst in a couple places.

Things seem to move freely - but I am holding off that until I can clean it up a bit.

Ways seem in pretty good shape - but will need a closer look after cleaning.

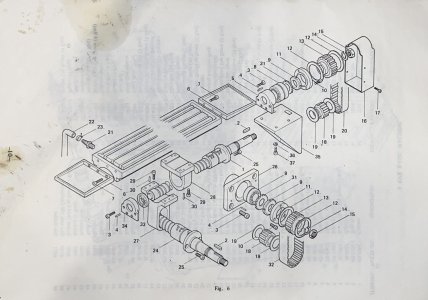

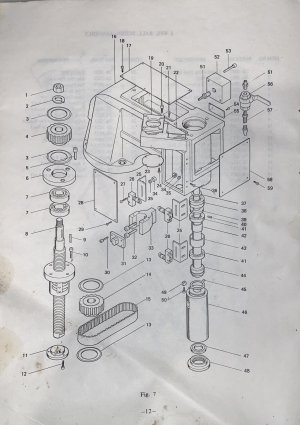

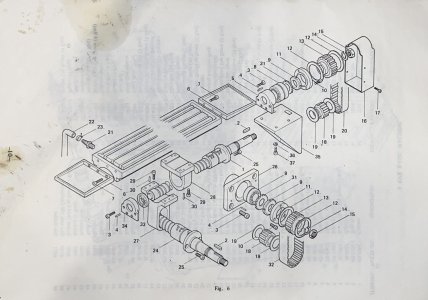

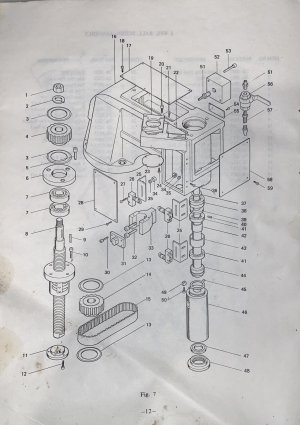

First order of attack will be sorting out a plan for adding hand wheels for manual operation.

A through scrub down and a rolling stand so I can learn the machine/ service, will also be nice.

I'll share my initial thinking in the next post regarding those handles.

Will welcome some critique and ideas on how I might tackle.

Pictures below.

Wife is of course, ecstatic...

Working on two stroke motors drove my initial interest to learn.

Started searching for a Bridgeport...

Next thing I knew - I was standing outside a barn, 2 hours from my house, looking at a 4K lb non working CNC Webb knee mill.

More about how I got there and this project in a moment - but first - a big thank you to Jim Dawson, who has been stellar in helping me get some basics in CNC. Let's just say, uncommonly patient...

Some pics and discussion here: https://www.hobby-machinist.com/thr...ted-to-cnc-for-sale.92613/page-11#post-856335

So - about the project.

I've been offered a Webb 5BVK mill from 1989.

For those unfamiliar with this thing - Its basically a Bridgeport. On steroids. Lots and lots of steroids.

4000 lbs and boxed ways.

It came from the factory as a CNC, and was loaded with the goodies of that time.

Power draw bar, automated self oil, lubrication and pan, DC brushed servo motors, 5HP spindle drive.

At first glance, a non operational 5BVK might seem like, well, a terrible place to start for a garage based machine.

1. It could take up half that garage

2. Being able to work on it is 2x harder when everything weighs 2x...

3. It is CNC only, and the CNC doesn't work. Literally there are no handles or places for them.

4-10. Fill in the blank. It's old, smells like cutting oil, and is covered in a layer of oily dust and nastiness.

With that said, there are a couple things that have kinda drawn me in.

1. While this beast is about 6 feet wide, the table is a moderate 42 x 13. Kinda perfect.

2. Without David Hasselhof's 1980's Night Rider boxes hanging off the side - its kinda a handsome and literally half as wide.

3. If I could figure out how to add handles - it would create a manual mill for me with opportunity to go full CNC in Phase II.

4-10. The price is: Free. (kinda buried the lead I suppose on that one).

My basic plan is to tackle this in two phases.

I. Get it cleaned up and operational as a manual. See how I like it and if it has any fatal flaws.

II. Take it CNC - with the ability to use manually as well. DC brushed motors will help allow nice tactile manual feel here (Again - Jim Dawson's input invaluable).

I am completely green with these machines and their use - but I figure learning HOW it operates before I try and OPERATE it is a pretty good base.

Pictures below of this beast (*outside for about 30 days, Im told...)

No significant rust to speak of - surface stuff at worst in a couple places.

Things seem to move freely - but I am holding off that until I can clean it up a bit.

Ways seem in pretty good shape - but will need a closer look after cleaning.

First order of attack will be sorting out a plan for adding hand wheels for manual operation.

A through scrub down and a rolling stand so I can learn the machine/ service, will also be nice.

I'll share my initial thinking in the next post regarding those handles.

Will welcome some critique and ideas on how I might tackle.

Pictures below.

Wife is of course, ecstatic...

Last edited: