- Joined

- Mar 2, 2013

- Messages

- 895

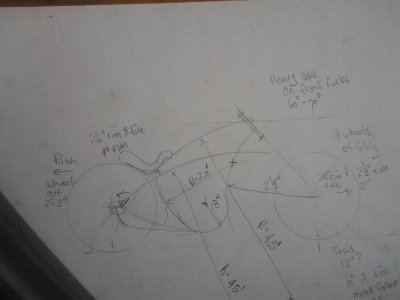

I started metal working again after a couple of decades away because i developed an interest in building bicycles for fun. I do a fair bit of riding when i can find the time... so it seemed like a natural fit:nuts: Well coming up to 2 years later i have built a couple of interesting bikes, bought some really cool metal working equipment and relearned how to lay down a decent weld bead all over again this is a new bike i am starting based off an older designi did.

this project started with a piles of bones, parts left over from other builds or practice piecs that were thrown into "the pile" This is a project not destinednto be exactly as the drawing, just as close as i can get on my 0 dollar budget.

this project started with a piles of bones, parts left over from other builds or practice piecs that were thrown into "the pile" This is a project not destinednto be exactly as the drawing, just as close as i can get on my 0 dollar budget.

hope you enjoy

rich

this project started with a piles of bones, parts left over from other builds or practice piecs that were thrown into "the pile" This is a project not destinednto be exactly as the drawing, just as close as i can get on my 0 dollar budget.

this project started with a piles of bones, parts left over from other builds or practice piecs that were thrown into "the pile" This is a project not destinednto be exactly as the drawing, just as close as i can get on my 0 dollar budget.hope you enjoy

rich