- Joined

- Jun 11, 2013

- Messages

- 731

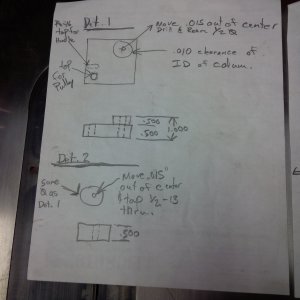

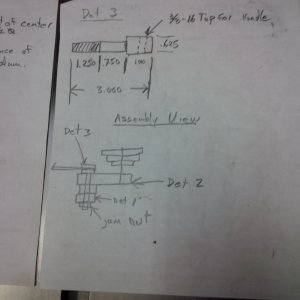

I have still not finished the complete project edit but thought I would get started posting.

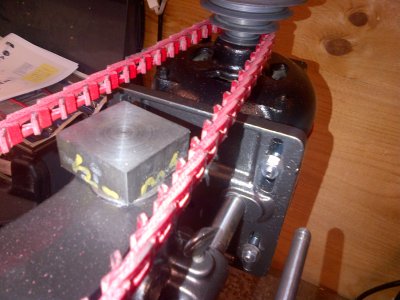

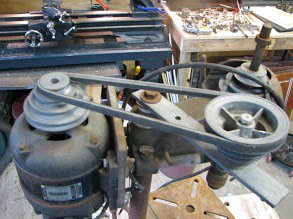

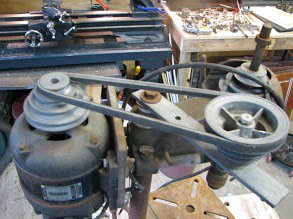

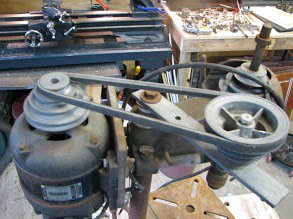

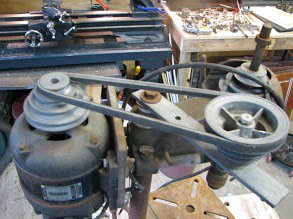

I picked up an older model atlas drill press for $60. It looked so lonely out in the cold in the for sale ad online. I knew I just had to have it.

I brought it home and surveyed the situation.

That's an interesting way to add another pulley. I think I need to reconsider that along the way.

But first we need to remove some rust and get things into reasonable shape. Some wire wheel work and time.

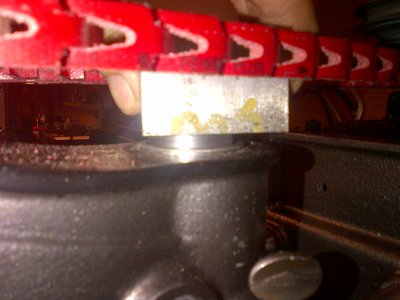

Next onto the column.

I was not happy with the finish on the table or the base. I indicated the table and it was way out. I need to deal with that at some point.

The cutout on the head is to allow the outboard (that's the only way I can describe it) pulley.

The motor still needs some work.

Stay tuned for more of this project.

I picked up an older model atlas drill press for $60. It looked so lonely out in the cold in the for sale ad online. I knew I just had to have it.

I brought it home and surveyed the situation.

That's an interesting way to add another pulley. I think I need to reconsider that along the way.

But first we need to remove some rust and get things into reasonable shape. Some wire wheel work and time.

Next onto the column.

I was not happy with the finish on the table or the base. I indicated the table and it was way out. I need to deal with that at some point.

The cutout on the head is to allow the outboard (that's the only way I can describe it) pulley.

The motor still needs some work.

Stay tuned for more of this project.

Last edited: