And now for the other direction. How well does the lead screw align to the bed front to back.

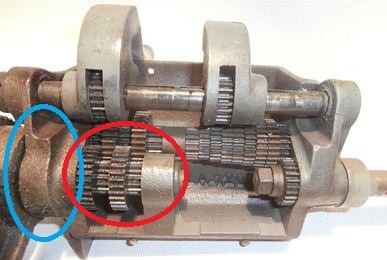

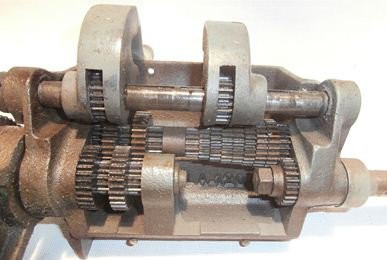

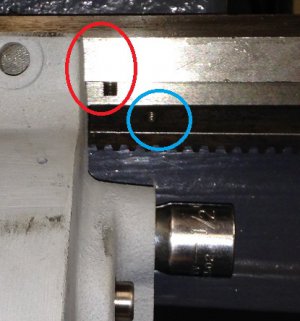

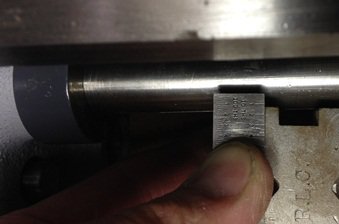

I again lined up the QCGB and shimed it in place with the lead screw installed. This time i shifted the gear box like i expect to do when i get the stud gear info. Interesting that the end of the lead screw once the box was shifted aligned perfectly with the end of the support. Hmm.....

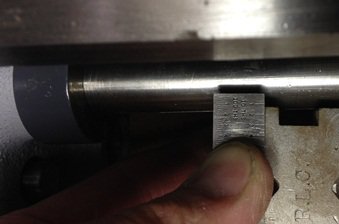

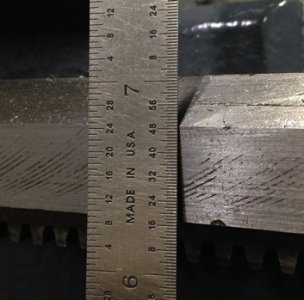

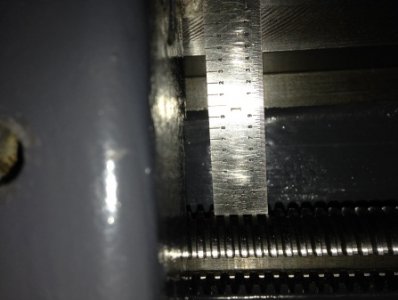

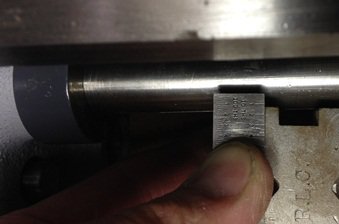

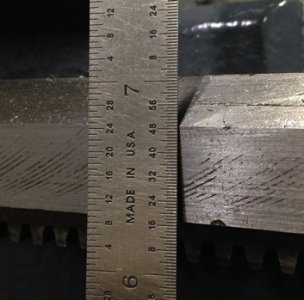

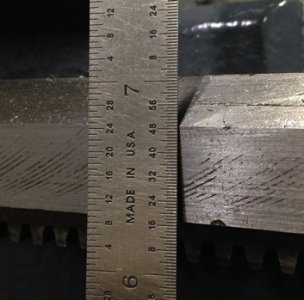

These pictures were hard to get. What i did was align the scale to the front edge of the bed which is directly over the lead screw. I sighted down the side of the bed's front edge and aligned the scale to that sighting. Once i aligned the scale, my "V" block, which was against the lead screw and also aligned parallel to the bed edge gave me the measurement. I then backed off to take a decent picture of the measurement. Otherwise i could not focus on the edge and the scale at the same time.

Head stock is about .130"

Left side of saddle with saddle to the right is about .110"

Tail stock is about .100"

I would say that i do not have the 11/32" issue with this system. I will reserve judgement though until i get my half nut installed. I think the best way to figure out my alignment is going to be with the half nut engaged and more or less letting it set the lead screw where it should be. It looks though like i am not too far off.

Can anyone measure for me your stud gear shaft? Or the distance the stud gear stands off from the reversing lever mount surface and some good pictures of the spacer? I am sure the design is the same, just farther out. I suspect i need to make a shaft.

The next topic will be the height of the bed. I am going to double post here as i am in catch-up mode right now with the projects documentation.

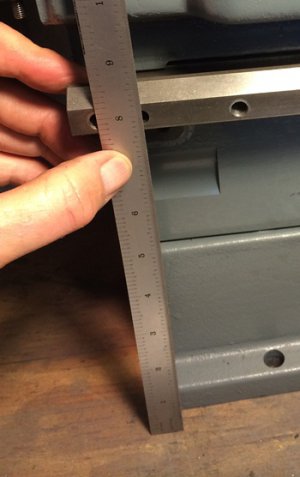

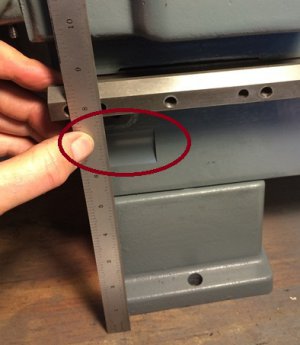

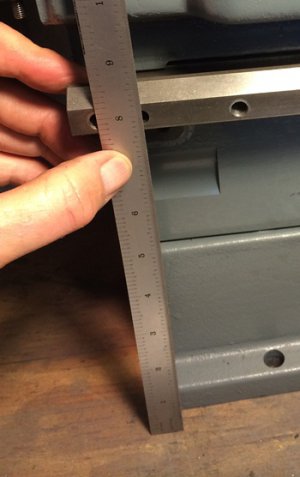

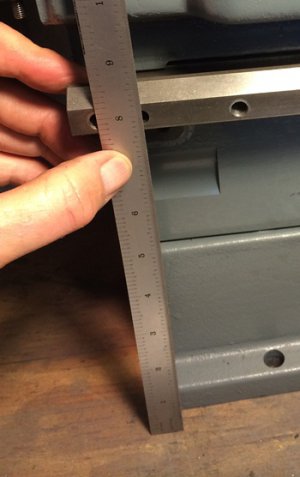

When i mounted the gear box before i took it apart i thought there was no way the selector levers would clear the deck. So how high does the bed need to be?

My gear box as you can see just barley clears the table. (Wish i had removed the towel for the picture.)

Measuring my Logan 400 the distance from the table to the "V" is ~6.8". I am measuring to the front face transition to the "V" as that is the comparable measurement i have.

The same measurement on a 9B is about 8.2"

The logan 400 is about 1.4" lower than the 9B. I do not know if the difference is in the risers or the bed. Seems like they would have re-used the bed casting but i do not have any supporting data except that i need to raise up the Logan 400.

I will do this by adding 1.5" square risers between the table and the lathe.

Matthew