- Joined

- Mar 31, 2014

- Messages

- 14

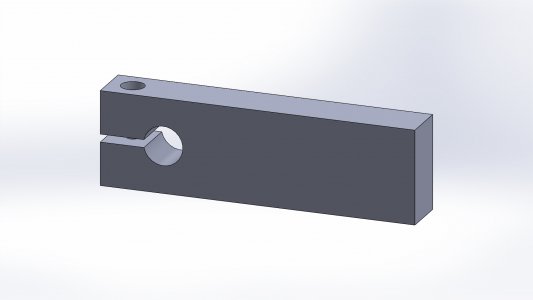

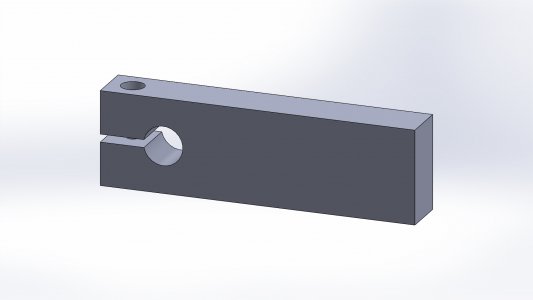

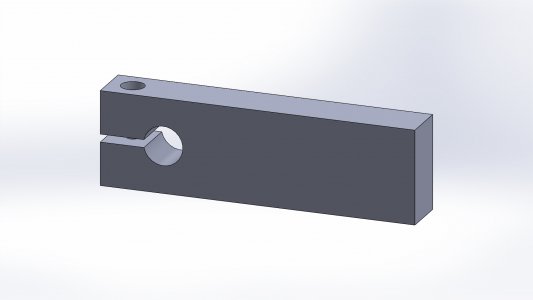

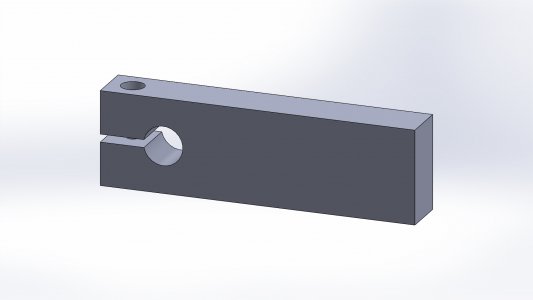

I need a part for a machine and I have no clue what its called. It needs to slide on a 5/8" shaft and lock down on it. And be able to slide back and forth once loosened so it can be tightened back down in different positions. The rough dimensions are 1.5" high, .75" thick, and 3.5-5" wide. I would just make it on my mill but my VFD hasn't come in yet and we need it ASAP at work. Id even thought about getting a lock collar and welding it to a piece of flat plate. The closest thing Ive found online is called a bottom mount shaft support and its too short.