- Joined

- Sep 20, 2012

- Messages

- 560

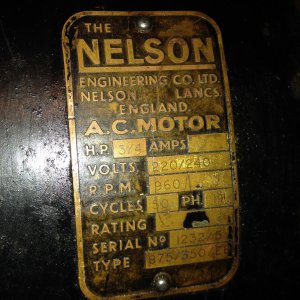

Some pics of what I found..

Dissolved insulation, I disconnected these two wires they come from the starter.

I'll be fitting new ones which shouldn't be affected by oil unlike these rubber ones.

Megger test showed a dead short on all four wires to the windings.

I then stripped off the outer sleeve of insulation from each one in turn, which were full of oil, just wiped the inner insulation clean,

then got a much better reading on three of them which was very encouraging.

The fourth one still showed a dead short, but I spotted the cause under some crud, broken insulation and bare wire.

So I will have to remove rest of the insulation from the wires and re-insulate them.

The oil will have to be removed and I'm still wary as to what to use as if it's shellac alcohol will harm that.

I'm thinking if I get a good reading when the wires are fixed I might just give it all a wipe over and leave it at that, I've seen pictures of motors still running that are clogged right up with grease and this one ran OK until a couple of days ago.

All this is new territory for me and I know almost nothing about the workings of these electrickery things but hopefully I will succeeded as I'd hate to loose this original motor, a modern lightweight one in my shaper would hurt my eyes!

Bernard

Dissolved insulation, I disconnected these two wires they come from the starter.

I'll be fitting new ones which shouldn't be affected by oil unlike these rubber ones.

Megger test showed a dead short on all four wires to the windings.

I then stripped off the outer sleeve of insulation from each one in turn, which were full of oil, just wiped the inner insulation clean,

then got a much better reading on three of them which was very encouraging.

The fourth one still showed a dead short, but I spotted the cause under some crud, broken insulation and bare wire.

So I will have to remove rest of the insulation from the wires and re-insulate them.

The oil will have to be removed and I'm still wary as to what to use as if it's shellac alcohol will harm that.

I'm thinking if I get a good reading when the wires are fixed I might just give it all a wipe over and leave it at that, I've seen pictures of motors still running that are clogged right up with grease and this one ran OK until a couple of days ago.

All this is new territory for me and I know almost nothing about the workings of these electrickery things but hopefully I will succeeded as I'd hate to loose this original motor, a modern lightweight one in my shaper would hurt my eyes!

Bernard