- Joined

- Dec 10, 2010

- Messages

- 195

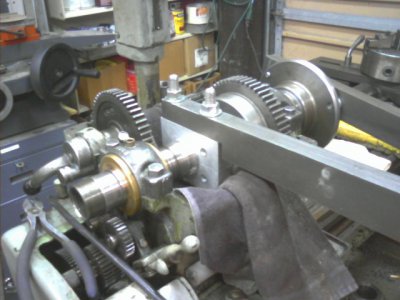

I wanted to take off the chuck before removing the spindle so after the usual methods failed to budge it, I resorted to the easiest of the three methods guaranteed to safely remove it. The lathe, being 75 yrs old, and not knowing when the chuck was installed is about half done but I only have a few hours a week to work on it. I won't get back till next Monday to see if the bucket method works. The 1" x 2" steel bar itself is heavy and there is about 25 lbs in the bucket. The chuck neck and inside have been thoroughly saturated with penetrating oil.