Hi Rod, I am new to this site, joining after having found your Cromwell rebuild project. First my congratulations! You've brought new life into another piece of great British engineering having faced quite a few challenges along the way! Well done!

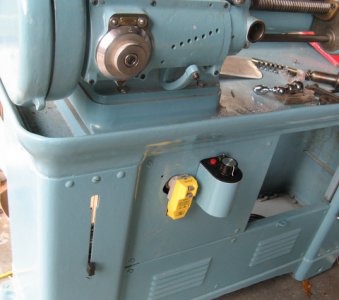

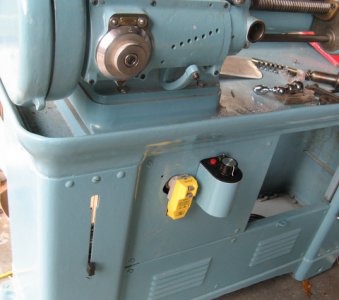

I have just acquired the same lathe and am now assessing what I have and what I have to do! My lathe came without the stand and motor, so for sure I have to consider what to do about that at some time. There are a few points I am not clear about so far, particularly about the headstock adjustment / disassembly. Before I launch right in, I hope you might point me in the right direction? At the moment the Bronze/Brass thrust end caps (the visible castellated C spanner ones at both ends) are not 100% tight. Should they be? I can rotate them just a bit either way by hand, but they cannot be undone by hand. What holds them tight? I have a cross section drawing from the manual but its not really conclusive on this so any advice would be appreciated. There appear to be a few differences between our lathes, a bit of product development I think. The base for my compound slide is a gunmetal casting, and not cast iron for example. Mine is number 946. Apparently there were only about 350 made, so quite rare as you know. I hope to hear from you.

Paul