- Joined

- Feb 7, 2014

- Messages

- 23

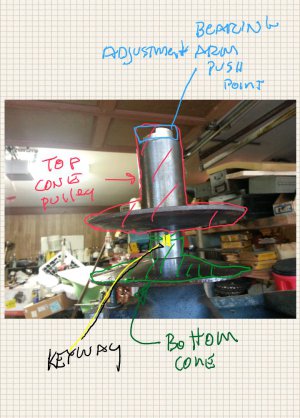

Bought this great drill press at an estate sale. The variable speed was froze up.

I have gotten it to open up some on the speed adjust pulley but would like to take it off and skim off some of the rust and polish up the shafts a bit in the lathe but I can not figure out how it comes off the spindle.

The only possible thing I can see would be to pull the bearing in the top and maybe there is a key in there somehow. The top movable pulley does not have a visable keyway but the shafts of the bottom pulley does.

Any ideas?