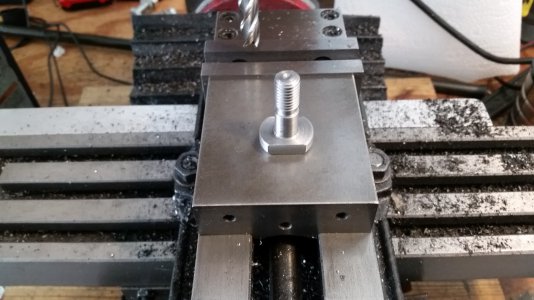

Man, I would have machine you a couple of new nuts for the cost of postage. I have the 1127VF-LB and my cross slide and compound look just like yours, but that doesn't mean they are exactly alike. While I didn't strip out any bolts, I did make new t-bolts that were wider and would have more grab area in the slots. This made me feel better.

I do suggest one mod to your machine, if you are comfortable with it. I took my tool post / compound off of the cross slide table and took everything apart to clean and lube it. When I had it apart, I remove the lock down ring plate that holds the compound in place. I didn't like the simple two bolt lock-down and felt it lacked much needed rigidity. I drilled 4 more holes in the piece, out near each corner. This provided a 4-bolt lock down which seems to be much more rigid. Just so you know, my lock down ring plate (not sure what to call it. it is the light gray piece in your photo with the cut out to see the angle markings on the compound) actually cracked right in the middle over the cut out for the angle markings. The design of that piece causes the part to bend significantly when it is tightened down. You can see the bend in your photos. I have not experienced any issue at all with the crack present and have not felt the need to change it. However, I have been interested in machining another one out of low carbon steel instead of cast iron, like it is made out of. I believe the steel would handle the bending stress better than the cast iron did.