-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First Aluminum Weld Project

- Thread starter Franko

- Start date

- Joined

- Dec 27, 2012

- Messages

- 36

Looking pretty good on the aluminum. It is a different world than steel, etc., no doubt.

Never sandblast aluminum, it impregnates the aluminum with the blast media and causes porosity in your weld. Prep with a dedicated grinder wheel, flap disc, stainless wire wheel or hand brush and clean with acetone.

NEVER clean with brake cleaner or carb cleaner they produce phosgene gas when heated.

http://www.brewracingframes.com/safety-alert-brake-cleaner--phosgene-gas.html

http://journal.publications.chestnet.org/article.aspx?articleID=1095693

Try some 1.5% or 2% lanthanated tungsten, I think you will like it for all welding not just aluminum. I use the 2% lanthanated almost indefinitely and have for the past couple of years.

I grind my lanthanated tungsten to a sharp point...some argue this but do not knock it until you try it. Also run hotter and move faster, it will prevent warping in the aluminum. I do a lot of aluminum fishing boat repair and fab decks etc.

This type of stuff.....

Never sandblast aluminum, it impregnates the aluminum with the blast media and causes porosity in your weld. Prep with a dedicated grinder wheel, flap disc, stainless wire wheel or hand brush and clean with acetone.

NEVER clean with brake cleaner or carb cleaner they produce phosgene gas when heated.

http://www.brewracingframes.com/safety-alert-brake-cleaner--phosgene-gas.html

http://journal.publications.chestnet.org/article.aspx?articleID=1095693

Try some 1.5% or 2% lanthanated tungsten, I think you will like it for all welding not just aluminum. I use the 2% lanthanated almost indefinitely and have for the past couple of years.

I grind my lanthanated tungsten to a sharp point...some argue this but do not knock it until you try it. Also run hotter and move faster, it will prevent warping in the aluminum. I do a lot of aluminum fishing boat repair and fab decks etc.

This type of stuff.....

- Joined

- Feb 24, 2015

- Messages

- 1,382

Thanks, goatdriver. Some of the best looking tig welds I've seen are on my Bass Tracker. It had a bunch of holes in the bottom when I got it. I paid a real welder to patch it up for me. I was impressed with his skill, laying on his back and welding the bottom without setting himself on fire.

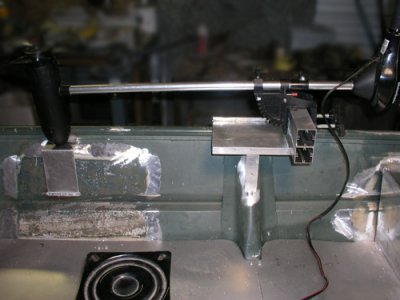

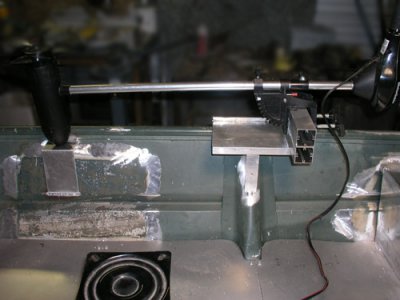

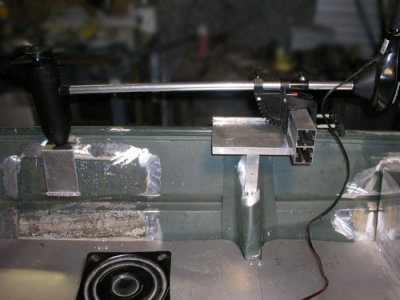

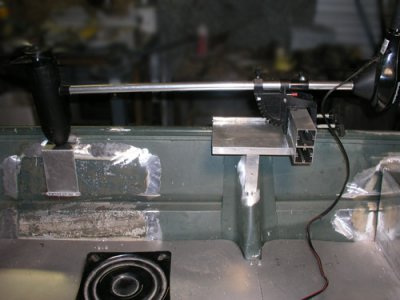

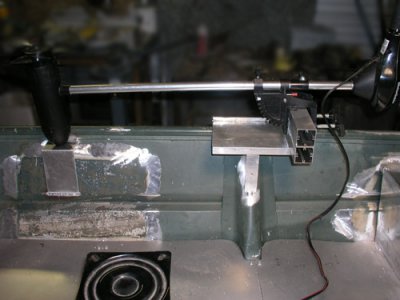

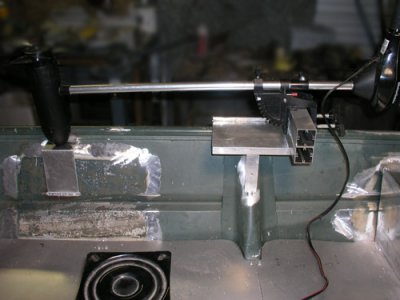

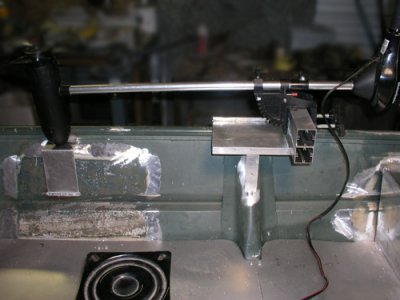

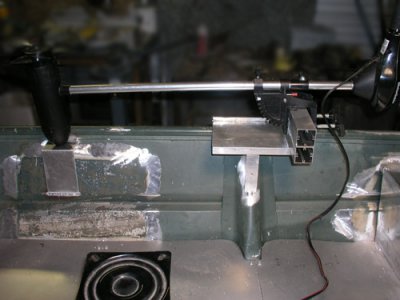

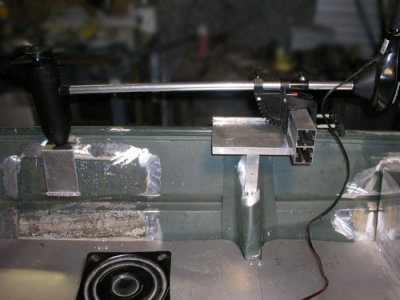

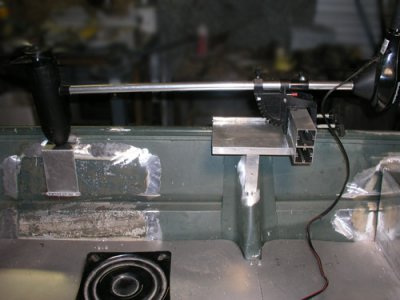

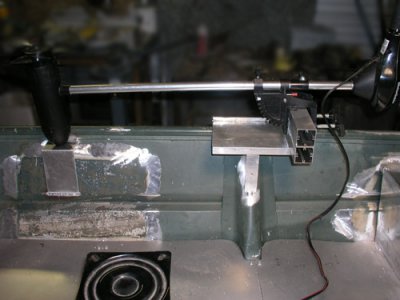

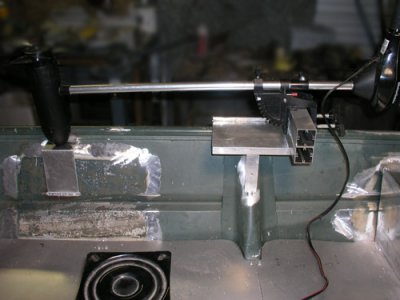

When I got that boat, I completely stripped out the inside and re-made all the decking and under supports with aluminum. Decks were 10th inch plate and supported with various angle and square tube stock, with heavy angle for seat base supports. I had it all screwed to the top plate and took it to the same welder guy, who welded it all up for me. It was all jigged up so he didn't have to anything but weld.

When I got that boat, I completely stripped out the inside and re-made all the decking and under supports with aluminum. Decks were 10th inch plate and supported with various angle and square tube stock, with heavy angle for seat base supports. I had it all screwed to the top plate and took it to the same welder guy, who welded it all up for me. It was all jigged up so he didn't have to anything but weld.

- Joined

- Feb 24, 2015

- Messages

- 1,382

I thought I might have another aluminum welding project. While refurbing my bicycle, I noticed a big split in one of the bottom back axle frame members. It looked like it was exploded from the inside with about a 2 inch longitudinal open split. The crack is parallel to a weld. I have no idea when it happened or how long it has been split.

I was talked out of trying to fix it by my local friendly welder who said welding would spoil the temper and weaken the tube, unless it could be re-tempered.

As it turned out, the frame on my bike is guaranteed for life, so the maker will send me a new frame or bike, depending on if they have a frame. It is about 10 years old. I'll know something this week. I cannot imagine what kind of stress would cause that tube to crack like that. It looked blown out from the inside.

The guys at the bike shop admonished me not to ride it, but I've been riding it for about 6 weeks. I don't think if it breaks it will be a catastrophic break. There are three other frame members holding the rear axle mount. I had a friend who had the same tube break in half on his bike and it didn't fall apart. He said it just got a little loose feeling.

It is good that the bike shop thinks the damage is so dangerous. It increases the likelyhood that they will make a good case to the maker to replace it.

I was talked out of trying to fix it by my local friendly welder who said welding would spoil the temper and weaken the tube, unless it could be re-tempered.

As it turned out, the frame on my bike is guaranteed for life, so the maker will send me a new frame or bike, depending on if they have a frame. It is about 10 years old. I'll know something this week. I cannot imagine what kind of stress would cause that tube to crack like that. It looked blown out from the inside.

The guys at the bike shop admonished me not to ride it, but I've been riding it for about 6 weeks. I don't think if it breaks it will be a catastrophic break. There are three other frame members holding the rear axle mount. I had a friend who had the same tube break in half on his bike and it didn't fall apart. He said it just got a little loose feeling.

It is good that the bike shop thinks the damage is so dangerous. It increases the likelyhood that they will make a good case to the maker to replace it.

Last edited:

- Joined

- Nov 27, 2015

- Messages

- 603

Looks like it was just fatigue. It's right next to that weld. Other places on the tube can flex more, but that area is stiffer, resulting in more stress in that area. All that's just a guess though.

Steve Shannon, P.E.

Steve Shannon, P.E.

Steve Shannon, P.E.

Steve Shannon, P.E.

F

Firestopper

Forum Guest

Register Today

I thought I might have another aluminum welding project. While refurbing my bicycle, I noticed a big split in one of the bottom back axle frame members. It looked like it was exploded from the inside with about a 2 inch longitudinal open split. The crack is parallel to a weld. I have no idea when it happened or how long it has been split.

View attachment 122862

I was talked out of trying to fix it by my local friendly welder who said welding would spoil the temper and weaken the tube, unless it could be re-tempered.

As it turned out, the frame on my bike is guaranteed for life, so the maker will send me a new frame or bike, depending on if they have a frame. It is about 10 years old. I'll know something this week. I cannot imagine what kind of stress would cause that tube to crack like that. It looked blown out from the inside.

The guys at the bike shop admonished me not to ride it, but I've been riding it for about 6 weeks. I don't think if it breaks it will be a catastrophic break. There are three other frame members holding the rear axle mount. I had a friend who had the same tube break in half on his bike and it didn't fall apart. He said it just got a little loose feeling.

It is good that the bike shop thinks the damage is so dangerous. It increases the likelyhood that they will make a good case to the maker to replace it.

Hi Franko,

That photo is interesting, The first thing that comes to mind is water possibly got in that section and froze. Most bike frame cracks/failures are of circumference nature from what I seen over the years. Curious to know if you could locate a small drilled hole at one of the ends of that section.

I do like to study metal fatigue when something interesting comes along.

- Joined

- Feb 24, 2015

- Messages

- 1,382

That's what is curious to me, Paco. I would expect a radial crack. It has at least one relief hole that I can find. It is on the inside (not top or bottom) by the axle and very small. I would think the tube would have to be just about completely full of water for freezing to cause such a crack. I don't see how that would be possible.

I'm no expert on metallurgy, but I have heard that an aluminum weld done wrong (somehow) it can cause a crack when it cools. I suspect that is the cause of the fracture, done at the time of manufacture. It created a invisible flaw that didn't show up until later. I think it is called a "hot crack," also known as hot shortness, hot fissuring, solidification cracking and liquation cracking. (I had to look that part up) I remember Jody the welder mentioning it several time on his videos.

I'm no expert on metallurgy, but I have heard that an aluminum weld done wrong (somehow) it can cause a crack when it cools. I suspect that is the cause of the fracture, done at the time of manufacture. It created a invisible flaw that didn't show up until later. I think it is called a "hot crack," also known as hot shortness, hot fissuring, solidification cracking and liquation cracking. (I had to look that part up) I remember Jody the welder mentioning it several time on his videos.

- Joined

- Feb 24, 2015

- Messages

- 1,382

Here is an update to the split bike frame saga. The frame warranty was denied by Giant Bicycles because the damage was caused by the tube filling with water and freezing. It says nothing about freezing on the warranty. They said it is a common problem up near the north pole where some people live.

I don't buy that at all. I think it is a design flaw if you put a hole that will allow water in a part that will freeze and burst, if you don't put another hole that will let the water out. Or, they could have simply plugged up the pressure relief hole once the part was welded.

But, it doesn't matter what I buy. Giant was unswayed by my reasoning.

What I ended up buying was a new bike. Not another Giant.

So, I don't have much nice to say about Giant Bicycles and wouldn't recommend anyone doing business with them. So there.

Last edited:

F

Firestopper

Forum Guest

Register Today

Sorry to hear about that Franco. The rupture looked like failures I seen in the past so my hunch was right as it appeared to be blown outward. I have seen .120"x1.5"x1.5" steel square tube fail for the same reason. The tube doesn't need to completely fill up with water to rupture during a hard freeze (I have seen this). The aluminum doesn't stand a chance against mother natures hydraulic pressure. I would massage the crack back down, drill two "stop drill" holes and grind a small groove along the crack and TIG over it. Unless you plan on jumping garbage cans like Evil Knievel a repair would hold up fine.

- Joined

- Feb 24, 2015

- Messages

- 1,382

Thanks, Paco. I've got a new bike but it should be fun to attempt to repair the crack and sell it with disclosure that it has been repaired. It is something I think I can TIG. I also have some aluminum brazing rod that might be worth a shot. The stress on that chain stay is tension. A linear crack on the length of the tube could be worse. I think if I TIG it up it will hold up for light duty riding.