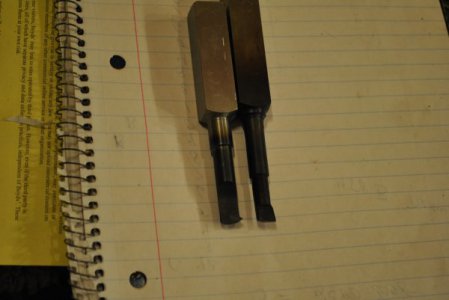

Why would you need all those different inserts for different TPI? I grind a 60 degree tool and cut any TPI With the same tool. Did I miss something here?I have one of the Shars internal threading boring bars pictured below. Runs around $38 + shipping, includes 1 insert - model # 404-2290. Style is 16 IR A60 or 16 IR AG60. Hit eBay for more inserts instead of Shars, you can get them for under $3. There's a picture below of it threading a piece of stainless.

By the way, make sure if you buy one of these bars you get the right sized inserts. 3/8" inserts are 16 series, 1/4" inserts are 11 series. The lettering after 16 or 11 should be IR for internal RH threads (E for external, L for left-hand threads). An AG60 insert is good for threads from 8-48 tpi, A60 is 16-48 and G60 is 8-14 tpi. They also sell them with UN suffixes; number in front is for that specific tpi. For example, 16 IR 14 UN is a 3/8 internal RH thread 14 tpi. 11 IR AG60 is 1/4" internal RH 8-48 tpi insert.

Bruce

View attachment 132758

View attachment 132760

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Internal Threading Bar

- Thread starter Sandia

- Start date

- Joined

- Jul 2, 2014

- Messages

- 7,594

To be completely correct, you need the correct sized flat at the tip of the V. So, with carbide, that means a bunch of inserts to do it correctly for different pitch threads. LH and RH tools are also different. With HSS, grind to fit, change as needed...Why would you need all those different inserts for different TPI? I grind a 60 degree tool and cut any TPI With the same tool. Did I miss something here?

- Joined

- Dec 8, 2013

- Messages

- 2,651

I made one like that (mine is 1" diameter). Round hole, square HSS bar. Works fine.I got a boring bar that has a slot for a short piece of HSS, I think it's about 1/8" square, maybe a touch more, with a set screw, each end of the bar has a slot that holds the HSS at a different angle, you break off a piece of a bar of HSS, grind the end how you want it, then put the HSS in the bar, and off you go to find your Uncle Bob. It was cheap too, under $10 at busybeetools. there are some larger versions of these as well. worked fine for making some 15mm left-hand-thread nuts.

http://www.busybeetools.com/products/boring-bar-d-e-1-2-sq.html

- Joined

- Apr 12, 2015

- Messages

- 1,463

Here's one that I make as needed. Super easy and works very well as both external and internal. Especially useful for small diameter internal threading. It is from Mad Modder site.

http://madmodder.net/index.php?topic=3523.0

The print for tool is a PDF document at the very bottom of #1 post.

I also have commercial thread tools too, both internal/external, but keep coming back to this one. It does a good job.

http://madmodder.net/index.php?topic=3523.0

The print for tool is a PDF document at the very bottom of #1 post.

I also have commercial thread tools too, both internal/external, but keep coming back to this one. It does a good job.

- Joined

- Nov 23, 2014

- Messages

- 2,606

I buy the AG60 style inserts which range from 8-48 tpi. Mentioned the others available just for info only. I think I mistakenly bought some IR 14 UN off eBay once, but I've used them for other than 14 tpi also.Why would you need all those different inserts for different TPI? I grind a 60 degree tool and cut any TPI With the same tool. Did I miss something here?

Bruce

- Joined

- Jan 22, 2011

- Messages

- 8,031

4

4GSR

Forum Guest

Register Today

Tony,

I haven't seen any of the vee bottom inserts used in over twenty years! Can you still buy them?

Ken

I haven't seen any of the vee bottom inserts used in over twenty years! Can you still buy them?

Ken

- Joined

- Jan 22, 2011

- Messages

- 8,031

Tool-Flo in Houston has them in their API catalog, and will grind just about anything not in the catalog. I have a few from the "old days" lol. That's why I made that bar. I already had an OD holder, and had a pile of internal inserts.

- Joined

- Apr 8, 2013

- Messages

- 1,979

- Joined

- Jan 22, 2011

- Messages

- 8,031

The problem with such threading tools is that there is no front relief to allow for the thread helix, unless you build a lathe fixture to cut the 60° disc at an angle, and then you have to know the projected apex of that angle to properly grind the top, and then as you sharpen it, that apex "rolls" around until you end up with zero or even negative front relief. I know lots of people use them, but they are technically at a disadvantage.