-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

End Mill Sharpener ?

- Thread starter rdean

- Start date

- Joined

- Feb 2, 2014

- Messages

- 1,061

It has been a little over a month since I started this project and a couple of weeks since I updated it.

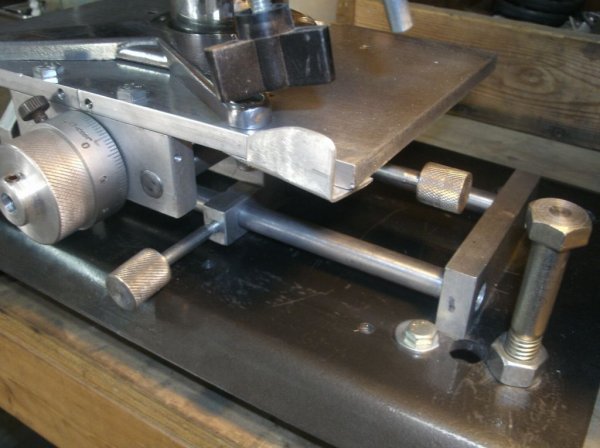

I was not happy with the grinder as I could not sharpen two end mills in a row and make them come out the same. There was too much slop in the table and it would move by itself in both the X and Y axis. The cam I made to lever the table solid did not work out too well as there was no way of positioning it in the same place each time so out it goes. I made a tab that would be used when doing the flutes that slid between the table and a stationary post to raise the table up and hold it against another post on the other side of the table. I thought this tab would solve the problem of the table creeping on me and it did make the table more stable but the creep was still there. I dissembled the entire table and added thumb screws to both X and Y axis along with removing any play I could in the slides. This seems to have done the trick as I had three identical 1/2" end mills that needed the ends sharpened. I was able to setup the first and then just change end mills to sharpen the others with out changing the Y axis.

I also made up a set of templates to use for setting the angle to the wheel for both end and flute cutting.

I have learned a lot about end mills and sharpeners in general and only now feel I can do a reasonably good job but there is more to learn.

Thank you

Ray

I was not happy with the grinder as I could not sharpen two end mills in a row and make them come out the same. There was too much slop in the table and it would move by itself in both the X and Y axis. The cam I made to lever the table solid did not work out too well as there was no way of positioning it in the same place each time so out it goes. I made a tab that would be used when doing the flutes that slid between the table and a stationary post to raise the table up and hold it against another post on the other side of the table. I thought this tab would solve the problem of the table creeping on me and it did make the table more stable but the creep was still there. I dissembled the entire table and added thumb screws to both X and Y axis along with removing any play I could in the slides. This seems to have done the trick as I had three identical 1/2" end mills that needed the ends sharpened. I was able to setup the first and then just change end mills to sharpen the others with out changing the Y axis.

I also made up a set of templates to use for setting the angle to the wheel for both end and flute cutting.

I have learned a lot about end mills and sharpeners in general and only now feel I can do a reasonably good job but there is more to learn.

Thank you

Ray

- Joined

- Feb 2, 2013

- Messages

- 3,627

excellent use of materials and machinery, as well as great mind putting them to use.

very nice work.

very nice work.

- Joined

- Jun 7, 2013

- Messages

- 10,087

If I were you, I would redesign the tooth rest so that it can rotate concentrically with the spindle, and graduate the mounting in degrees. This allows for clearance to be set for different diameters on end mills when grinding the OD. just lowering the tooth rest to achieve the same result causes binding of the rest on the flute of the cutter. This is how Harig's air bearing fixture is designed. I use it for all my end mill sharpening on my #1 Norton cutter grinder.

- Joined

- Feb 2, 2014

- Messages

- 1,061

After using it for several months now I agree your suggestion would make sharpening easier. I may look into a redesign in the future but since I am only sharpening a small number of mills for my self it works fine for now.

Ray

Ray