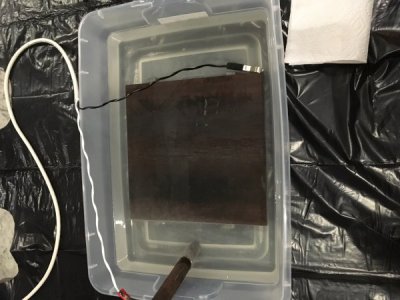

3 hours in the pickling bath - already seeing a good amount of bits sitting on the bottom of the drum and a good amount of bubbles forming on the surface. I plan on letting this go for 24+ hours then neutralizing in an alkaline bath (baking soda and distilled water) before lightly coating with oil to prevent any surface rusting as I continue on with the fabrication. I still plan to fly cut / surface the plate on both sides before locating and drilling/boring the many holes. This plate is destined to be my first tooling/fixture.

Since I am waiting for the carbide tooling to arrive for the surface operation I am in no rush.

Since I am waiting for the carbide tooling to arrive for the surface operation I am in no rush.