ok so you all saw my previous thread about the $400 Heavy 10, well I sold and got that 10k and i love it except two things.

ok so you all saw my previous thread about the $400 Heavy 10, well I sold and got that 10k and i love it except two things.When moving the carriage and i can feel grainy and a little rough feeling through the apron handwheel. Best way to inspect it for damage I would imagine is the rack and taking the apron off?? What woukd I look for??

Also I found a 4 foot bed in literally prisitine pristine condition for 150 bucks locally. It came off a Model c. My question is I know I have to drill out the third countersink hole for the QCGB, but with the 10k head stock bolt on like a 9a would? I also got the minty 4 ft lead screw with the bed as well for 50 bucks.

What challeneges will I be up against putting my 10k onto this 4 ft model C bed?

I am going to break down this machine go throught it and rewick and repaint it and it will be my first cherry popped with dissassembling a lathe and Im stoked. But Im relying on some help from all you generous bright minded folks!!!

Any information is greatly appreciated!! Im a former Marine with No friends out here In connecticut. My only friends are named Interenet and Youtube lol

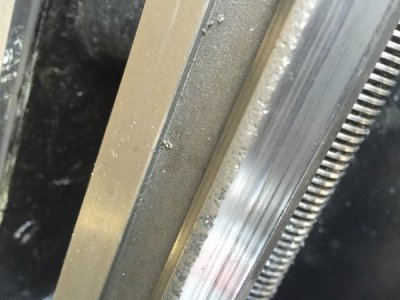

As you can see in the pictures I have attached the pitting on the bed is on both sides of the beds on the v-ways. About 8 inches long and nasty. Hence the reason for getting the new 4 ft bed.

Thanks!!!