-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

School me on collets for the Atlas lathe, 3c, 3at,or both?

- Thread starter Uncle Buck

- Start date

- Joined

- Jan 22, 2017

- Messages

- 104

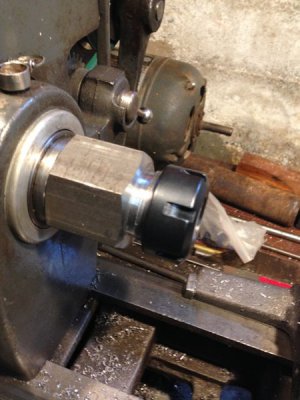

Rob, was there any particular reason you went with the hex stock instead of round? Or was it "available material?"Here are a couple of pics of a ER32 collet chuck that I made. I used 2" hex stock to make it. Yes you can purchase the collet nut, it will be a metric thread. I purchased the collets and nut from Amazon.

Looks nice - considering ER40 right now.

Jim Korman

It can be used for a 6 sided dividing head for cutting a hex on round stock. I also used a piece of 2" square stock to make one for my Atlas Mill. Again another dividing head. Also you can use a wrench to take it off instead of spanner pins.

- Joined

- Mar 22, 2014

- Messages

- 847

The idea of making my own ER32 collet chuck to fit the spindle of my lathe is intriguing. I thought the tapered bore that accepts the collet was super critical and had to be ground at a precise angle. Can I get away with setting up the angle on my compound and using a boring bar?

Last edited:

What is the deciding factor between ER32, ER40 , and others?

Size and cost. I choose ER32 because it went to 3/4" which is the size of the headstock on my Atlas lathe and also the nut was smaller than the 2" hex stock that I used.

The idea of making my own ER32 collet chuck to fit the spindle of my lathe is intriguing. I thought the tapered bore that accepts the collet was super critical and had to be ground at a precise angle. Can I get away with setting up the angle on my compound and using a boring bar?

While the angle is important I do not think that it is super critical. I did not grind mine and do not seem to have any problem.

I purchased my collets before making the chuck. I placed a piece of 5/8" drill rod (what I had) in my 3 jaw chuck and placed the 5/8" collet on that to set the angle. I then used a boring bar to cut the internal taper.

One thing about making it on the lathe that you will be using it on there will be very little run out.

- Joined

- Dec 25, 2011

- Messages

- 10,511

Size and cost. I choose ER32 because it went to 3/4" which is the size of the headstock on my Atlas lathe and also the nut was smaller than the 2" hex stock that I used.

Rob,

Thanks for posting the photos. I still hadn't managed to find a photo that I have somewhere.

Larry,

By "Size", he means several things. Physical size (both length and outside diameter of the collets themselves), Maximum diameter that the family will hold, and Minimum diameter that it will hold..

- Joined

- Mar 22, 2014

- Messages

- 847

Harold Hall has a nice tutorial on making your own ER chuck: http://www.homews.co.uk/page130.html