As some of you are aware, my 618 arrived to me in less than stellar condition; needing a new rear gear. I am happy to report I have since completly diassebled the lathe and replaced the rear gear and another gear needing replacement. In addition, I also replaced the lead screw and half-nut (which I bought brand new) and stripped the unit to the bare metal, primed and painted her. She is now completely assembled and ready for use.

However, I have decided to add a VFD (which I now have in my posession) and a 3-phase motor (should be here today or tomorrow) and solid tube belting. So while I await the UPS guy, I am reading up on the VFD etc.

I do want to pass along some rather disturbing details regarding the replacement screw I bought from Atlas; it comes with a wider (ever so slightly) bushing than the original. This would be no big deal if the gears did not run on such tight tolerances, but they do. So it ended-up causing two gears to rub due to the bushing being wider and forcing the main screw out further into the gearing mechanism. So,..I had to take the whole thing apart again and put the old bushing on. You would think one would notice the size differential, but you can't. The difference is so small that you cannot discern the difference in size unless you lay them on a flat surface and view them from a perfect 90 degree angle. Or, of course, measure them.

Needless to say, I'll be in touch with Atlas on Monday to share my sentiments with them.

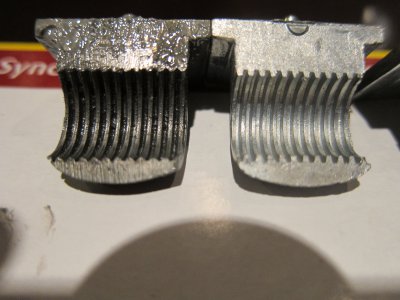

An observation worth noting; while my half nut and screw were in pretty good shape, when I received the new one, the difference was stunning. My perspective is if something needed replacing, it was going to be replaced. So now that it is all together, it is really nice to see the unit move under the power of my hand.

I got pretty good at taking everything apart and putting it back together. I had plenty of time on my hand so I did things until I liked them, period. Pics attached. Ask questions if you like.

Cheers~

However, I have decided to add a VFD (which I now have in my posession) and a 3-phase motor (should be here today or tomorrow) and solid tube belting. So while I await the UPS guy, I am reading up on the VFD etc.

I do want to pass along some rather disturbing details regarding the replacement screw I bought from Atlas; it comes with a wider (ever so slightly) bushing than the original. This would be no big deal if the gears did not run on such tight tolerances, but they do. So it ended-up causing two gears to rub due to the bushing being wider and forcing the main screw out further into the gearing mechanism. So,..I had to take the whole thing apart again and put the old bushing on. You would think one would notice the size differential, but you can't. The difference is so small that you cannot discern the difference in size unless you lay them on a flat surface and view them from a perfect 90 degree angle. Or, of course, measure them.

Needless to say, I'll be in touch with Atlas on Monday to share my sentiments with them.

An observation worth noting; while my half nut and screw were in pretty good shape, when I received the new one, the difference was stunning. My perspective is if something needed replacing, it was going to be replaced. So now that it is all together, it is really nice to see the unit move under the power of my hand.

I got pretty good at taking everything apart and putting it back together. I had plenty of time on my hand so I did things until I liked them, period. Pics attached. Ask questions if you like.

Cheers~

Last edited: