Hi everyone! This post is 5 years old and found it because I just acquired an acro-grip collet closer advertised for Colchester Student 1800, Master 2500 or similar size lathes. I've been looking for one of these for a long time for my small Chipmaster. Saw a few getting sold on eBay for crazy amount of money, around £500 here in the uk, these where advertised for the smaller size of Bantams or Chipmasters but as I've been saving pictures from previous sold listings. Some of them had dimensions (rulers/tape measures next to them in pictures) and I could compare them to this one and got to the conclusion that there is not much difference other than the: spindle to 5C adaptor bush, rear end spindle adapter, and the arm for fixing it to the back of the machine. All the rest of the parts look exactly the same, the spindle tube lenght, O/D, I/D not sure of the internal parts, like bearing or such, but just got it home and fits the Chippie nicely. All I need to make now is the three parts. The spindle bush which is pretty straight forward to do. I've done spindle bushes before, so it shouldn't be a problem. By the way, to make things clear, the Chipmaster has an 4.5MT taper in the spindle nose. Not 4mt, not 5mt and not 3mt, it's 4.5MT standard taper. I have the original bush and is stamped on it MT 4-1/2 STANDARD TAPER. Not sure of bantams, but would say similar size ones would have the same taper.

Back to the collet closer, the rear end spindle adapter is made out of two parts. A larger splined locating ring, and another part that makes the difference of being fitted to a smaller or larger lathe. In case of a large lathe it has a bigger O/D and its short, as in case of a small lathe like a Chipmaster it's longer and smaller O/D to fit the spindle. The two are bolted together with three screws, these are also used for setting it to run true. Thank you Cheeseking for the uploaded pictures, now I know the purpose of the screws. This part would be even easier to make than the spindle nose bush. I could come up with dimensions but if there is anyone here that could help would be greatly appreciated.

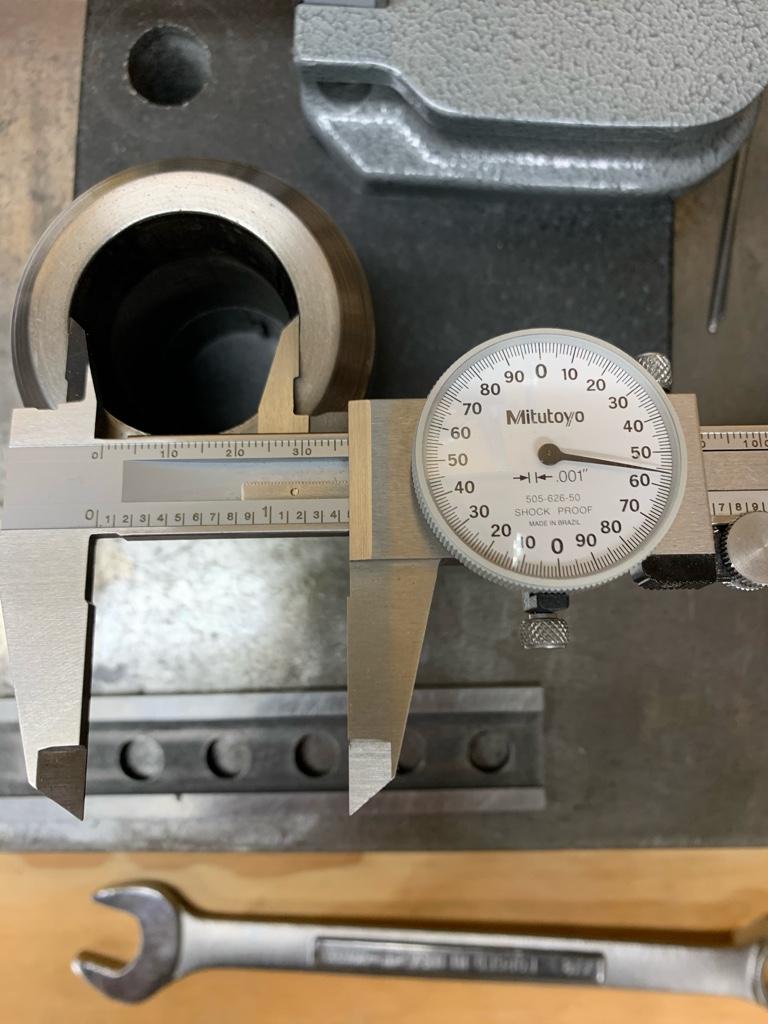

Because the are two dimensions that I would need to come up with, the spindle nose bush length and the rear end spindle adapter, chances are that it will not work by just guessing from pictures. So, even in case anyone has only the spindle nose to 5C bush please post pictures with rulers, calipers or just the dimensions.

The arm attaching to the back of the machine is adjustable, this is probably the easiest to make and differs from machine to machine. The Chipmaster, at least mine has two tapped 1/4" holes. These wouldn't really do I think...

Attached is a napkin drawing of the spindle 5C bush I made quickly at work. The only thing that is needed are the missing dimensions. If anyone could fill up these it would be greatly appreciated.

Thanks